Motion control is similar to chess in that it takes minutes to learn the rules (allowing the creation of very basic indexing systems) but years to master the ability to perform advanced motion control. This article will review the different types of motion controllers currently on the market, and the pros and cons of each option.

By Jeramé Chamberlain • Manufacturing Engineer Manager | Nippon Pulse America Inc.

The main job of any motion controller is to command the motion of a mechatronic assembly, including any motors and other mechanical components such as actuators. Whether control is needed for a simple point-to-point positioning application or for multi-axis interpolated moves, choosing the right motion controller can have lasting effects on the final product. A controller with insufficient computing power or capabilities that fail to meet a machine’s motion control needs can degrade that machine’s performance and abilities. On the other hand, overly powerful or robust controllers can add unnecessary system cost.

Choosing a motion controller can have its challenges because they range in complexity and capability — from very simple indexing systems to full-fledged motion control systems.

Indexing systems deliver simple control

An indexing system is a category of controller used for simple position or velocity control with very few if any other features. Indexing systems for the most part have no (or very limited) acceleration control, which limits the number of set speeds and types of acceleration that can be employed. The key feature of the indexer is that they are very inexpensive, as they typically consist of a microprocessor with a limited amount of code. These simple systems have become very popular in the hobby and maker markets due to the availability of open-source software, which has made indexing a project easy.

However, one disadvantage to using an indexing system is that, while generating a speed and direction command is simple to do by toggling outputs on a microprocessor, more complicated motion profiles need more time and experience to master. This is because indexing systems are not really intended to function as complete motion controllers.

Indexing systems are commonly used for motors with integrated controller and drive, sometimes called smart motors. Indexers are also very commonly seen in single-axis motor drivers and some integrated circuit (IC) drivers.

Motion control systems deliver multiple capabilities

Motion control systems deliver multiple capabilities

On the other end of the controller spectrum are full-fledged motion control systems. These controllers can operate motors at high speeds and allow multiple ways to adjust the speed. They employ inputs and outputs to monitor basic safety factors such as emergency stops, inhibits, end of travel limit, homing and a variety of other features. The inputs and outputs also allow for simple machine-control logic and advanced features such as multi-axis control, coordination of motion, pre-buffered movement, speed changes, positional offsets, and host of other advanced features.

Full-fledged motion controllers can be lumped into two major categories — designed from scratch or COTS units.

1. Designed-from-scratch motion-control units

Motion controllers that are designed from scratch are the most popular option for original equipment manufacturers (OEMs) who typically build controllers in large quantities. These controls are built from discrete components and a custom printed circuit board (PCB). Building their own systems allows OEMs to customize their controllers with only the specific features used by their equipment, which drives the component count (and ultimately, eventually, the cost) down, only using what is needed for a specific application.

The major components or ICs used come in two basic categories:

- Application-specific ICs (ASICs) devices are designed to control motors and handle the intensive calculations involved in the profile generation, multi-axis coordination and many advanced features, as well as handle the safety devices involved in their operation.

- General-purpose programmable devices (including CPUs, microprocessors, and FPGAs) are not solely for the control of motors but can be programmed for this use. These devices can also serve to execute other tasks related to the operation of human-interface devices and other functions of the final device.

The component cost for these two options are very similar. However, the ASIC device is regarded as a safer design choice, as the design and algorithm for motor control is time tested. Because the algorithms used by the ASIC device are encoded fully into the semiconductor device itself and don’t use a separate program, the algorithm can run much faster than a general-purpose programmed device. Also, there’s no way for a hacker to adjust the algorithm at a later date because it is a hardwired device that can’t be changed with programming.

On the other hand, general-purpose programmable devices are more flexible due to the fact they can be programmed to do much more than just profile generation. Some general-purpose devices even offer “blocks of code” as basic motion indexers, which provide limited motion control capability. These blocks of code must be adapted by the developer to add the advanced features needed for each application. Because these are programmed devices, it is possible for them to be accessed and reprogrammed by hackers, so they are generally not considered secure. General-purpose devices run slower and are prone to interruptions from other processes, which isn’t an issue with ASIC devices.

Both ASIC and general-purpose devices need supporting firmware and circuit designs, which also need an experienced programmer and an electronic engineer. General-purpose devices need a programmer that is experienced in setting up and designing the device being programmed. In addition, advanced motion control requires specialized engineering experience. Even with a full engineering team, designing a from-scratch motion controller can be very slow. The ASIC motion control device will let design engineering teams go to market faster, as the algorithm for the motion is already fully tested and ready to run.

Because general-purpose device performance is driven by a market that is always looking for faster performance, they generally deliver a much shorter life cycle than ASIC motion control devices. Either way, the end of -life for an ASIC or general-purpose device necessitates complete redesign.

2. Ready-built off-the-shelf motion-control units

Ready-built or commercial off-the-shelf (COTS) units are systems that have already gone through the design-from-scratch process described above, and the completed package is sold as a finished unit. In addition, the firmware and circuit designs are fully vetted and ready to use.

These systems are usually sold as a standalone box, PLC, or PC board-level designs. The biggest market for these types of motion controllers is interdevice applications, and they are widely used by machine designers and smaller OEMs.

Key advantages of standalone motion controllers include:

- Controllers that are simple to program often support one or more of the following industry standards: G-code, ladder logic, LabView integration (a form of Basic-style human-readable programming) as well as other easy-to-understand codes or even direct programming using buttons and an HMI display.

- Often available with one or more standard communication interfaces such as CAN bus, EtherCAT, Ethernet, Powerlink, PROFIBUS, RS-485, SERCOS, and USB.

- The ability to store and execute a standalone program without the need for a master device (such as a PC). Alternately, the standalone program can be integrated into a larger system, allowing a master device to send commands over an interface as described above.

- Ready-built units are designed with an application or market in mind, and may incorporate standard connections, I/O, and axis controls that are common to the markets for which they were designed.

The downside of off-the-shelf units:

- Units have a set number of features and are not easily adaptable. This makes it difficult for them to be used outside of the market for which they were designed, or to continue use as technology advances beyond the scope of the original control system.

- Full-featured packages that are more flexible are very expensive, limiting their appeal for use in higher volume applications. In addition, not all features that come standard with the unit are necessary for every application — which means OEMs may be paying a premium for features that the application will never use.

The path for an OEM to develop a motion controller design from scratch can be long and slow, and we have seen an uptick in the number of OEM manufacturers using ready-built motion controllers to prove out a design, because they are easy to program and get up and running. However, once the equipment has been designed around a ready-built motion controller, the system must continue to use the ready-built system, even with its higher cost, or else be fully redesigned to a custom, from-scratch system.

There’s currently no product that bridges the gap between designed-from-scratch and COTS motion controllers. When we look at the market, there’s a need for a full-fledged motion controller that is easy to use with a proven design, at a price point that is cost-effective for higher-volume applications. Even as a bridge from ready-made to design-from-scratch, an intermediary product would offer a quick avenue to custom-tailored control with a much shorter design cycle.

The following individuals contributed to this article: Sacha Marcroft, Motion Group V.P. and Territory Manager at Western Automation Inc.; Brian McMorris, President at Futura Automation LLC; and Kevin McNicholas, V.P. Sales Channel Development at Allied Motion Technologies Inc.

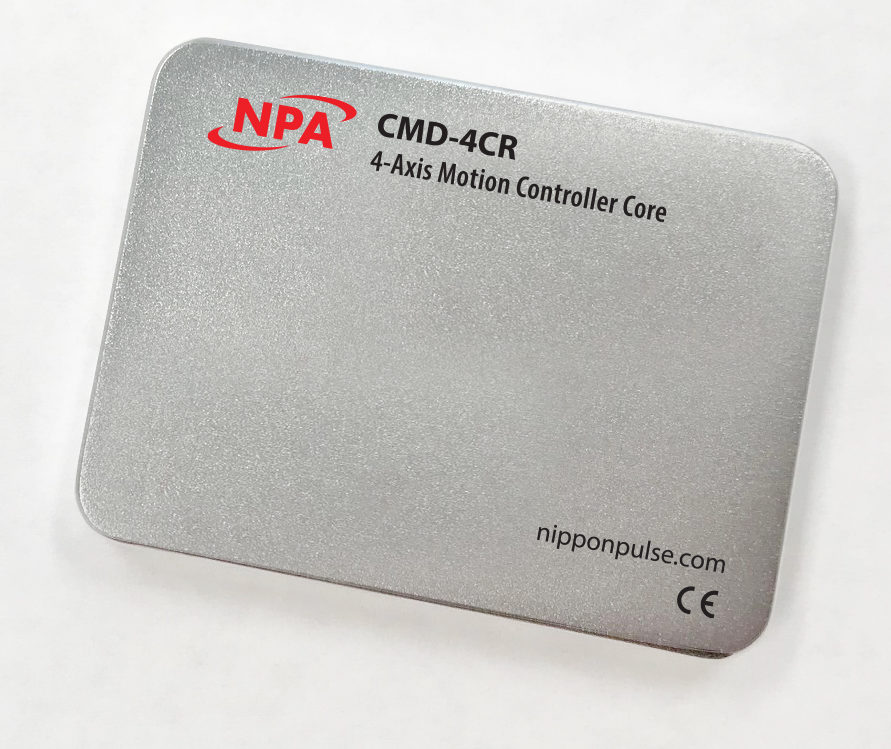

On the horizon: Motion controller that will bridge the gap

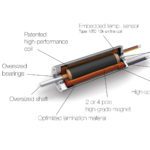

Nippon Pulse America will soon introduce a new category of powerful and flexible motion controllers to bridge the gap in the motion market. The secure, easy-to-use hybrid IC is called the Commander core, and is built around the Nippon Pulse PCL6045BL ASIC to combine the benefits of COTS designs with the customizability of design-from-scratch ASIC and FPGA controllers. Commander will be sold as a ready-built motion controller that eliminates the need to source components from additional suppliers, and will also be free from dependency on other components’ lifespans (and the huge revisions to products in the field such lifespans usually entail).

For OEMs, the Commander core will serve as a cost-effective tool to allow ramping up to higher-volume production with minimal design time and support. It will reduce development time for the from-scratch motion controller segment, as systems can be quickly proven out with the Commander Development Kit, which includes a development board and core module. The OEM can then incorporate the core itself into their final custom PCB design.

The motion controllers will be suitable for use in 3D printing equipment • lab automation • textile machines • printing presses • gaming machines • medical imaging machinery • small robotics • CNC milling machines • welding equipment • semiconductor manufacturing equipment • and vending machines.

Leave a Reply

You must be logged in to post a comment.