Motor and control system developer Nanotec Electronic US Inc. (en.nanotec.com) has unveiled its first rotary encoder with the latest optical encoder product series — the NOE1. This compact rotary encoder is ideal for applications that employ small stepper or BLDC motors and require accurate positioning.

Aside from a good controller and the motor, the rotary encoder is also a vital component of applications demanding accurate and high-resolution positioning.

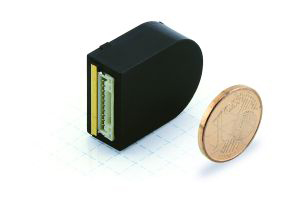

Medford-based Nanotech has specifically developed the three-channel optical encoder NOE1, in response to the growing need of applications in medical technology and other fields for compact rotary encoder. Measuring just 20 mm x 26 mm x 10 mm, the NOE1 optical encoder seamlessly fits small BLDC and stepper motors. It also makes measurements using photodiodes, which read off a code disk.

Featuring a resolution of 2000 pulses per revolution, the NOE1 is also equipped with a quadrature, which optimizes the resolution to 8000 increments per revolution. This corresponds to around 40 increments per 1.8 degrees step for a stepper motor, and enables users to measure the commutation angle during field-oriented control operation. Even at slow speeds, the NOE1 also delivers an operation with good synchronization. For higher interference immunity, the line driver has been integrated into the encoder’s compact housing.

The NOE1 is ideally suited for BLDC motors requiring high-resolution positioning. For stepper motors, the all-new NOE1, together with the company’s closed loop controls offering performance Beyond MicroStepping (field-oriented control with sine commutation), made way for new fields of applications in areas where precision positioning requires high torque.

Leave a Reply

You must be logged in to post a comment.