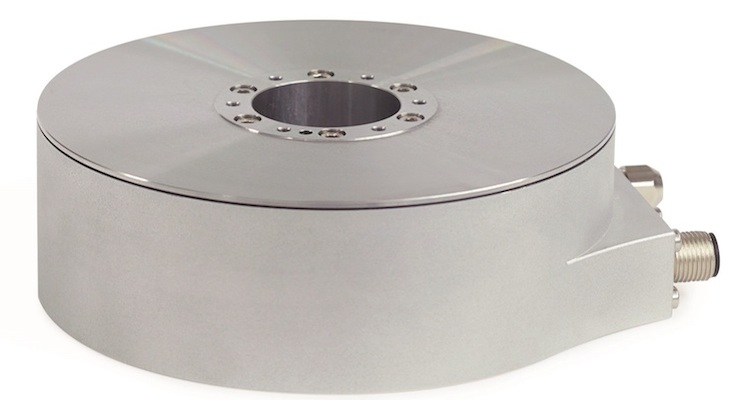

The new SRP 5000 angular positioning system from HEIDENHAIN incorporates its high accuracy MRP 5000 angle encoder with accomplished bearing technology along with a unique ETEL torque motor with ultra-low detent torque. This combination allows for high stiffness with low cost of ownership and can easily replace rotary air bearing systems used for metrology. Industries that could take advantage of the SRP 5000 system are semiconductor manufacturing, metrology, and micromachining.

The SRP 5000 is compact in size and is only 46.3 mm in height and 124 mm in diameter.

The system can be ordered in incremental or absolute models, where the incremental versions have encoders with 30,000 signal periods per revolution and system accuracies down to +/- 2.5 arc seconds. The absolute version has the same accuracy level and resolutions to 28 bits via the EnDat 2.2 interface.

The slotless iron-core ETEL torque motor has a peak torque of 2.7 Nm, a rated torque of 0.387 Nm and the detent torque is just a mere 0.2% of the rated value. The motor is rated for 300 RPM and permits an extraordinarily smooth motion.

The SRP 5000 is best used with the AccurET position controllers from ETEL as absolute peak performance can be achieved with regard to dynamics, thermal management, and position stability. Other controllers can be used, however thermal overload protection must be maintained in the controller.

For more information visit www.heidenhain.us.

Leave a Reply

You must be logged in to post a comment.