Elgin, Ill. – A new, compact 4-quadrant positioning motion controller with integral output stage is now available from Dunkermotoren USA to control brushless and brushed DC motors as a slave in widely used CANopen networks or in stand-alone operation with digital or analog IO.

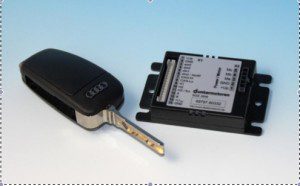

Two versions of the new control are available in the same compact, power-dense package size of 51.7cc, slightly larger than a matchbox. The BGE 3508 model is designed for 10-30V input with 75W of continuous and 225W peak power, while the BGE 6005 model can produce 120W continuous and 300 W of peak power with 60V input.

These new controllers are suitable for use with brushless or conventional brushed DC motors similar to Dunkermotoren’s BG and GR/G ranges. Information about the motor’s rotor position can be supplied to the positioning controller either by the voltage or by an encoder in the case of commutator motors or, for brushless motors, by Hall sensors or an incremental encoder. The controls incorporate protection against over-voltage, low voltage and excessive temperature.

If 4-quadrant digital speed control is desired, the control can be commanded to run in either direction, stop and hold with torque, and stop without torque (coast) through digital inputs. Other inputs can switch between programmed speeds or allow for a variable analog speed reference. Accel/decal ramps for the motor can also be programmed. The control offers the capability for a motor to function as a stand-alone, programmed servo which interfaces to the rest of the machine via digital and analog IO.

The new BGE 3508/6005 controllers offer many different modes of operation to choose from, such as analog or digital torque control, analog or digital speed control and digitally selectable position control (relative, absolute, and modulo).

Designed for volume OEM applications, the Dunkermotoren BGE 3508/6005 controllers offer a design alternative for restricted space applications where the additional length of an integral control motor may not be feasible. They can also be encapsulated to provide additional protection in extreme environmental conditions.

CANopen is the most widespread application layer in non-automotive control applications and market researchers predict that by 2015 some 400 million CAN chips will be used annually in a wide range of applications such as medical equipment, heavy vehicles, door control systems and throughout commercial and industrial automation systems.

Visit www.dunkermotoren.com to find out more.

Leave a Reply

You must be logged in to post a comment.