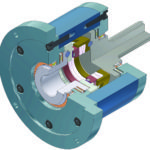

A new 16-page, full-color catalog from Force Control Industries details the Posidyne line of clutch brakes featuring Oil Shear Technology for long service life with no maintenance or adjustment. Ideal for high cycle count applications (up to 250+ CPM), from 240 to over 78, 500 lb/in. torque ratings, they are available with air or hydraulic actuation. Totally enclosed sealed housings allow them to operate in severe environments. Various cooling options include fan, water, oil-to-air and forced lubrication. Wash down, Marine Duty, severe and hazardous duty options are also available.

This new literature is available in print by request, or can be downloaded here. Posidyne clutch brakes, also available as clutch only, require no maintenance or adjustment, and boast service life that is often 10-times that of traditional dry clutch brake systems. They are ideal for a wide variety of applications where precise and repeatable indexing are required, especially in lumber manufacturing/sawmills, steel mills and service centers, packaging, food processing, fiberglass insulation production, roofing shingle manufacturing, concrete block plants, coal sampling, production machines, marine – shipboard and port materials handling, rail loading and more.

For more information visit www.forcecontrol.com.

Leave a Reply

You must be logged in to post a comment.