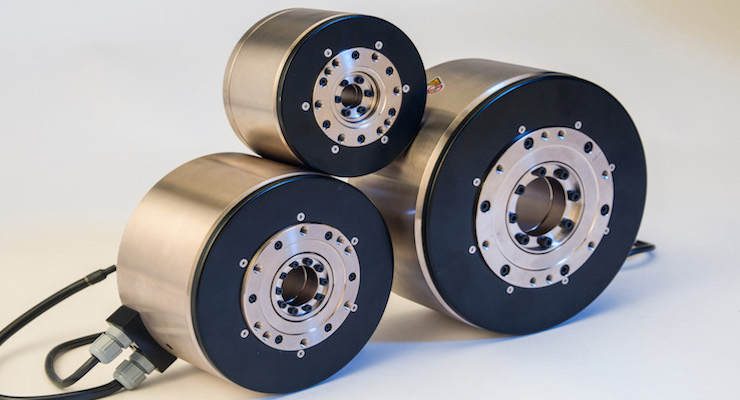

A new direct-drive servomotor from the Drives & Motion Division of Yaskawa America, Inc. packs a new level of performance into a more compact size.

The new Yaskawa SGM7F line of direct-drive servomotors delivers from 4 to 35 Nm of torque in a device as small as 2.1-in. high and 5.3-in. in diameter (53 x 135 mm). This size advantage makes it possible to apply the mechanical benefits of a direct coupling between a servomotor and a load in tighter spaces than ever before. Machine designers can use the SGM7F to make automated machinery more compact, freeing up valuable space on crowded plant floors.

The chief advantage of direct drive products is the ability to attach a load directly to the servomotor, allowing a full range of motion control without the need for a shaft coupling or gearhead. The SGM7F also offers a superior level of torsional stiffness and virtually eliminates mechanical backlash. This yields an output that minimizes damage to components and maximizes positioning accuracy and repeatability. The SGM7F also offers a host of other advantages, including:

- An open core design that adapts easily to shaft mounting and allows wiring to pass through easily

- 24-bit encoding for exceptionally precise motion control

- A self-cooled design that generates a low level of heat

- A design that is ideal for applications which require downsizing and shorter cycle time

The SGM7F line offers eight different models to suit a wide range of industrial applications, including dial tables, transfer lines, die actuators, electronic parts assembly, and print registration.

For more information, visit www.yaskawa.com.

Leave a Reply

You must be logged in to post a comment.