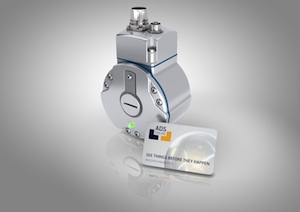

Schaumburg, Ill. – Leine and Linde has released an updated version of their ADS (Advanced Diagnostic System) encoder diagnostic tool. The new ADS Online is the company’s proprietary advanced encoder diagnostic tool tailored to supporting condition-based maintenance. The system analyzes rotary encoder condition and warns of impending faults before they occur. This is especially useful in large complex machinery such as that used in the exploration of oil & natural gas as well as wind turbines and paper-converting machines. It allows for service to be performed only when necessary and in ample time to avoid unforeseen stops in production.

Factors that can affect service life include temperature, operating speed, and vibration. Because encoders are subject to wear (service life can vary from a couple of years to a couple of decades), an ADS Online system allows users to better predict and schedule maintenance at convenient times instead of waiting for inopportune breakdowns.

Currently available on Leine & Linde’s model 801 and 803 rotary encoders, ADS Online operates by a connection from the encoder’s diagnostic system direct to a PC or to an Ethernet network which provides access to encoder functioning or trends anywhere worldwide. With the assistance of PC software, users can also obtain detailed analyses. There are plans to offer ADS Online on other Leine & Linde encoder models in the near future.

Encoder applications for ADS Online include the ability to set custom warnings to ensure vibration doesn’t exceed specific damaging levels, program levels for frequency and shaft speeds to indicate overspeed or standstills, ensure that the machine does not overheat, prevent voltage drops in the power supply, and choose to receive an automatic warning when the encoder reaches a certain operating time.

For more information, visit www.heidenhain.com.

Leave a Reply

You must be logged in to post a comment.