Encoders are everywhere — and are vital in industrial, aerospace, energy, automotive and robotic applications. Operation in many of these applications involves operation in severe conditions. Consider a particularly extreme case: When building a robot that may one day mine for water on Mars, how does an engineer decide on the most suitable components to use? There’s usually a tradeoff between durability and precision … so what’s the solution for these more challenging designs? Let’s find out.

Proliferation of encoders in automation and burgeoning robotics market

The latest Research and Markets report predicts that the North American industrial-robotics market will grow at a CAGR of 12.26% for 2015 to 2019 … and with vendors using advanced technologies to develop independent robotics to remain competitive in the market, encoders are as important as ever in these applications.

Rotary encoders provide critical information about the position of motor shafts and with it their rotational direction, velocity and acceleration. With the emergence of affordable, agile, mobile robotics applications in an ever-expanding industrial and domestic setting comes the need for new techniques and solutions in rotary-position encoding. They are vital components in the motion-control feedback loop of industrial, robotic, aerospace, energy and automation applications.

Mitigating the encoder-technology tradeoff

Today, the most commonly used encoder technologies are the optical and magnetic types, but the challenge for design engineers has been in choosing between the trade-offs of the two. The optical approach offers the best accuracy, but with reduced reliability due to the fragility of its optical disk. The magnetic approach, on the other hand, provides greater durability, but with less accuracy, especially as temperature increases within the application.

Remember the Vernier caliper? There are countless instances where looking to the history of technology can provide an idea for something new today. The Vernier caliper developed over 30 years ago has spurred development of a new encoder type that offers an accurate, precise and rugged solution for today’s applications.

Capacitive sensing is commonly used for touch switches, where a user’s finger acts as the second plate of a capacitor. Touch switches are known for their resistance to dirt, water, and overall abuse, because they have no moving internal parts. However, the uses of capacitive sensing go beyond such basic on-off switches, with the ubiquitous digital caliper as a mass-market example.

When applied to encoders, capacitive sensing uses patterns of bars or lines (with one set on the fixed element and the other set on the moving element) to form a variable capacitor configured as a transmitter-receiver pairing. As the encoder rotates, an application specific integrated circuit (ASIC) counts the line changes and also interpolates to find the precise position of the encoder and direction of rotation.

Capacitive operation for durable and reliable encoder

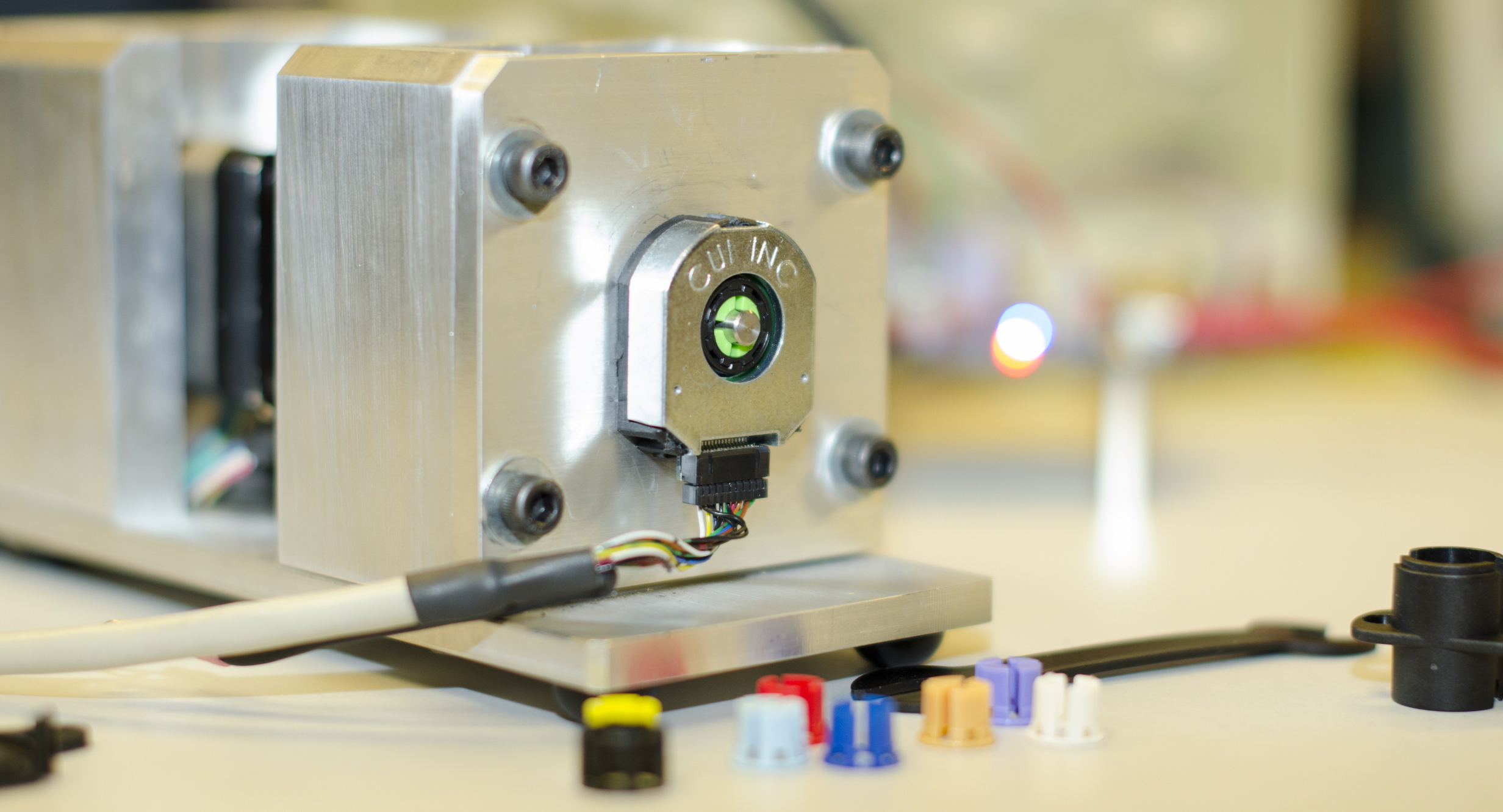

Design engineers no longer need to make the difficult choice between the attributes that optical and magnetic encoders force: short and long-term reliability versus output accuracy. The capacitive encoder can deliver the durability of a magnetic encoder and the accuracy of an optical in one package. The AMT encoder series from CUI Inc. is tried and tested in myriad extreme conditions.

#Encoders from @CUIInc based on #capacitive technology eliminate normal design tradeoffs Click To TweetConsider one application: A manufacturer of baking automation equipment consistently had issues at customer sites with flour dust and other contaminants degrading optical-encoder reliability on a key production unit. This frequently led to line-down situations to let personnel replace and re-zero the encoder. By swapping the optical encoder for a capacitive one, the problem disappeared.

In another case, a manufacturer of offshore drilling equipment needed the motor assembly to be submerged in oil due to high pressures associated with the application. So engineers switched to a capacitive encoder because of its ability to operate without interruption in nonconductive fluids such as oil.

In fact, the AMT encoder excels in the most severe environments — whether surveying crops, automating a factory process, or preparing to mine for water on Mars.

Leave a Reply

You must be logged in to post a comment.