WEG has extended its SSW900 series of soft starters to include frame size E for the current range of 480 to 670 A. The series previously consisted of four frame sizes A to D, covering output currents from 10 to 412 A in the voltage range of 220 to 575 V 3-phase ac.

These compact high-performance devices with integrated PLC, provide fully programmable algorithms for controlling induction motors, as well as fully flexible torque control and are designed for industrial and commercial use.

Thanks to soft starting and integrated protection functions, the SSW900 ensures energy-efficient and reliable operation of electric motors. It’s suitable for a wide range of applications, including ventilation fans, pumps, stirrers and mixers, conveyors, extruders, dryers, industrial ovens and ball or hammer mills. This makes the SSW900 suitable for sectors such as petrochemical, mining, textile, woodworking, plastic processing, metalworking, water and wastewater management, and food and beverage.

“The new frame size extends the SSW900 series of soft starters at the upper end of rated motor power,” explained Johannes Schwenger, head of product management low and medium voltage drive systems Europe at WEG. “In addition, new features such as CANopen are now available in the entire series. Convenient in use, the SSW900 with integrated PLC matches the generated torque to the load and keeps the start-up current as low as possible. There are also numerous protection and monitoring functions that are integrated to ensure the reliable operation of the electric motors.”

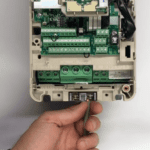

The soft starter supports direct motor connection in star or delta configuration, as well as string connection. This allows the three motor phases to be wired directly to the three thyristor pairs of the SSW900. As a result, the soft starter only has to provide 58 % of the rated motor current (corresponding to the phase current), allowing a smaller device to be used for the same power level. The integrated bypass relay extends the lifetime of the device. Ease of use is further enhanced by a real-time clock as well as diagnostic and status query functions.

Another benefit of the SSW900 is the LCD display and HMI that simplifies user operation and allows users to make program adjustments quickly and easily. Commissioning and programming are assisted by wizard functions. USB functionality integrated in the user interface enables configuration of the soft start parameters using the free Windows-based WPS software, as well as programming of the internal SoftPLC using the free WLP software.

For more information, visit www.weg.net.

Leave a Reply

You must be logged in to post a comment.