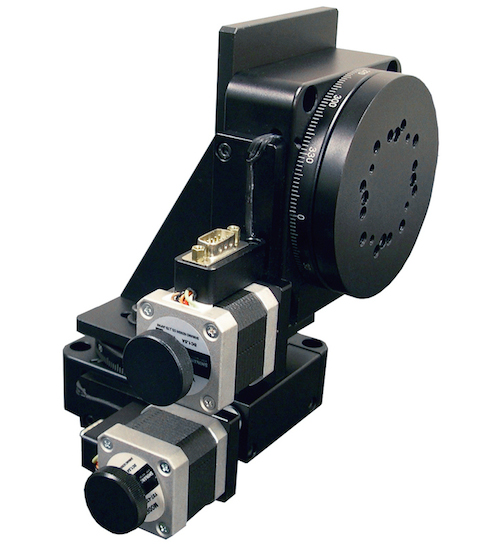

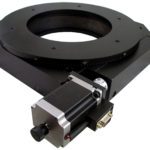

OES (Optimal Engineering Systems, Inc.) has added new high-resolution, motorized, pan-tilt stages to its extensive line of motion control products. The new stages are available in two sizes: the PT60-1 Pan-Tilt Stage is a combination of two 60 mm (2.362 in.) rotary stages and the PT100-1 is a combination of two 100 mm (3.937 in.) rotary stages, set at a 90° angle to each other. The rotary stages of each Pan-Tilt stage features a high repeatability of 0.005° (18 arc-sec), a positional accuracy of 0.005° (18 arc-sec), and a resolution of 0.001° (3.6 arc-sec) (or 10 micro-steps per step motor driver in use). These Pan (horizontal table)-Tilt (vertical table) stages are suitable for scanning, testing, inspection, assembly, positioning, laser and micro machining, pointing optics and cameras, and other applications.

The pan and tilt axes on both stages have precision V-grove and crossed roller travel guides and are driven by a worm gear with just of 0.005° (18 arc-sec) of backlash. These compact, easily integrated Pan-Tilt stages weigh just 2.0 kg (4.4 lb) for the PT60-1 and 4.4 kg (9.75 lb) for the PT100-1 and load capacities are 10 kg (22 lb) and 20 kg (44 lb) respectively).

Each axis is driven by a standard bi-directional stepper motor with a knob for manual adjustments and each rotary axis has a vernier scale for setup. The knob on each motor can be replaced with an optional encoder for position verification. Travel speed of each axis is 12° per second with a stepper motor or for higher speeds and closed loop operation, servomotors are available. Electrical connections are made using 9-pin DB-9 connectors.

The PT60-1 and the PT100-1 Pan-Tilt Stages can be ordered as complete plug-and-play systems with a multi-axis controller, joystick, trackball or keypad.

For more information, visit www.oesincorp.com.

Leave a Reply

You must be logged in to post a comment.