The new IndraDyn S series MS2N carefully performs intelligent scans all the way up to the motor. This is possible because the individual measurements of each individual motor, as well as saturation and temperature data, are stored in the respective motor’s memory and automatically processed by IndraDrive controllers. This information greatly increases the precision of the torque and reduces the tolerance range to a fraction of previously accepted values. Also, for the first time, the servo motor also provides data. This allows machine tool operators to implement Industry 4.0 applications, such as condition monitoring and predictive maintenance, economically and without additional components.

The new IndraDyn S series MS2N carefully performs intelligent scans all the way up to the motor. This is possible because the individual measurements of each individual motor, as well as saturation and temperature data, are stored in the respective motor’s memory and automatically processed by IndraDrive controllers. This information greatly increases the precision of the torque and reduces the tolerance range to a fraction of previously accepted values. Also, for the first time, the servo motor also provides data. This allows machine tool operators to implement Industry 4.0 applications, such as condition monitoring and predictive maintenance, economically and without additional components.

Thanks to the new motor construction and an optimized electromagnetic design, this new generation is able to achieve significantly reduced torque ripple. This is especially important for maintaining constant path velocity and thus, increased product quality, as in free form milling. In addition, the developers at Bosch Rexroth have reached up to 30% higher torque density. The motors are significantly more compact despite their enhanced performance. Machine manufacturers can thus use smaller motors in existing drive tasks or use more power within a given motor compartment. Up to five times overload capacity guarantees the fastest acceleration and optimum dynamism for all sizes. With different degrees of rotor inertia, machine manufacturers can offer application-oriented design for different masses on the axes.

Thanks to high-quality materials, the MS2N motors achieve significantly greater continuous power, even at higher speeds. As such, the new development is perfectly suited for use in driven tool axes in lathes. Also, thanks to their optimized winding technique, the motors help to reduce internal losses. Thus, the new generation accomplishes dramatic increases in energy efficiency.

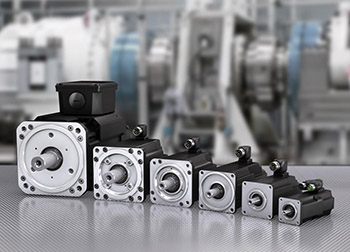

Rexroth offers the IndraDyn S series MS2N in six sizes with up to five lengths each. The series covers the power range from 4 Nm to 360 Nm maximum torque and 0.8 Nm to 148 Nm continuous torque at standstill. Machine manufacturers can choose from three encoder systems, all finely graded in both precision and resolution. For the electrical connection of power and encoder signal, Rexroth provides an innovative single cable connection, as well as conventional two-cable solutions with highly flexible cable options and practical quick-lock.

Bosch Rexroth

www.boschrexroth-us.com.

Leave a Reply

You must be logged in to post a comment.