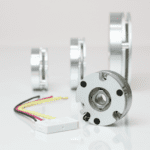

SEPAC’s new line of extremely thin power-off brakes, the UTSEB Series (Ultra Thin Spring-Engaged Brakes), is offered in five standard frame sizes from 1.14 to 2.68 in. in diameter and lengths from 0.47 to 0.67 in. The ultra-thin design provides a short package size when the brake is mounted to the rear of a motor; and when mounted to the front, there is room for mounting a pulley. What makes the UTSEB’s small size exceptional is the increased torque-to- diameter ratio performance — offering static torques of over 22 lb-in. The low-inertia UTSEB also has minimal backlash, less than 1.5°.

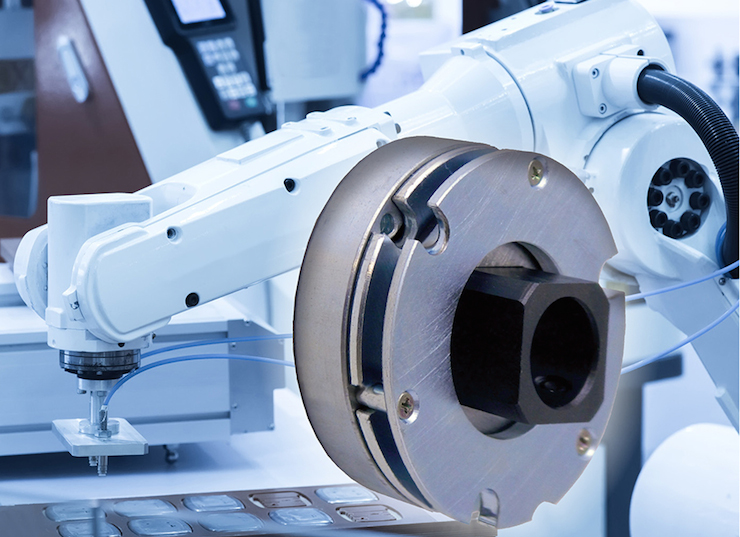

Used for power-off engagement applications, the UTSEB is equipped with a PWM controller to reduce heat and save energy, making it a cost-effective solution for continuous duty applications in robotics and automation systems. Energizing the brake’s UL Class F insulated coil with 24 Vdc, the PWM controller then provides 7 Vdc to hold the brake in the power-on/brake-released position. This dramatically reduces ongoing heat generation by conserving current and wattage draw. When power is turned off, the coil’s electromagnetic field dissipates, allowing the springs to push the armature plate into contact with the long life friction disc material. This squeezes the friction disc between the pressure plate and the armature plate, thus transmitting torque to stop/hold the friction disc, hub, and shaft.

The UTSEB is RoHS compliant and is available with wide ranging customized interface dimensions. As a standard service, SEPAC provides comprehensive in-house design resources to modify the UTSEB configuration to accommodate most customized application requirements.

For more information visit www.sepac.com.

Leave a Reply

You must be logged in to post a comment.