Nuttall Gear has announced its implementation of the NQA-1 Nuclear Quality Assurance Program. This program allows Nuttall Gear to provide nuclear safety-related components directly to its large base of installed product in nuclear power facilities around the world.

Nuclear facilities can now reduce their costs significantly by purchasing new components, rebuilds and replacement parts directly from Nuttall Gear.

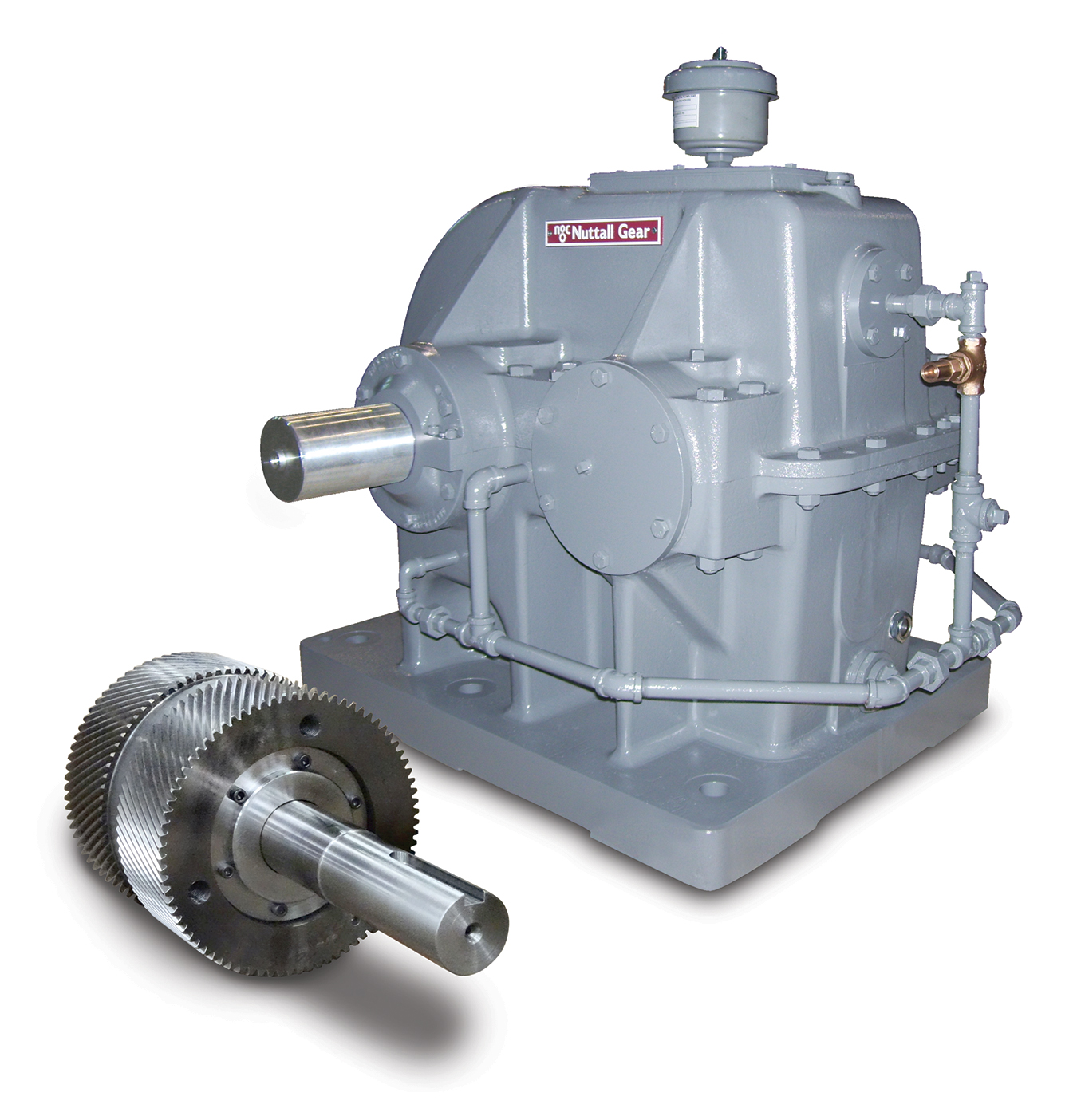

Nuttall Gear provides a wide variety of custom solutions for nuclear power applications including speed reducers, boiler feed pumps, high and low pressure pumps, auxiliary pumps, generator drives, cooling fan backstops and pressurized water reactor anti-rotation devices.

Factory services available from Nuttall Gear include rebuilds and refurbishments, engineering, reverse engineering, and gear drive testing. Field services including on-site repair and rebuilds, inspections and evaluations, laser alignment and installation assistance are also offered. More after the jump.

By partnering with Nuttall Gear, customers can be assured that repairs and replacement components are genuine OEM quality and manufactured at its ISO 9001:2008 certified facility to meet or exceed original design specifications.

For more information, visit nuttallgear.com and download the new Gearing Solutions for the Nuclear Power Industry brochure (P-8021-NG) from the literature portal.

Leave a Reply

You must be logged in to post a comment.