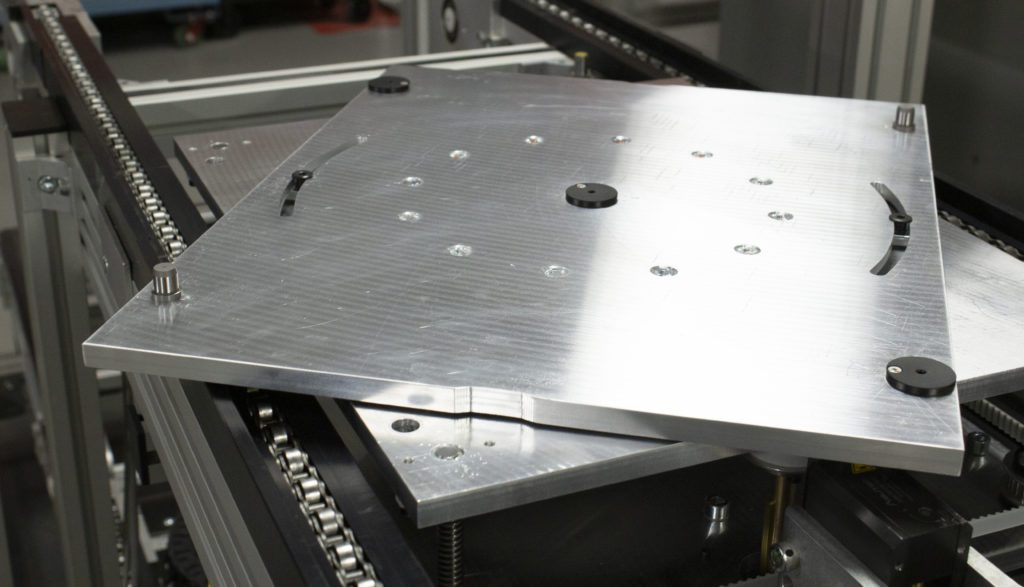

Pallet-handling conveyors optimize manufacturing, assembly, and testing processes by conveying product on workpiece pallets. The workpiece pallet provides consistent and stable conveying — regardless of the product’s current shape and future evolution down the line.

By Kate Nadeau • mk North America

Pallet-handling conveyor systems are reliable, durable, and highly intelligent systems that integrate and connect production lines. These conveyor systems allow for product to interact with robots and cobots in very specific ways. They also provide more ergonomic workspaces for their human operators. These conveyors can accumulate and store product, or they can be used to precisely position and locate products — or they can do both of these things. The ways in which pallet-handling conveyors can improve, optimize, and modernize manufacturing lines are nearly limitless.

The problem is that many of these very systems are rife with inefficiencies. What’s more, these inefficiencies can affect a variety of industrial automation components — not just conveyor systems.

Pneumatic systems are the culprit

Compressed air plays a crucial role in pallet-handling conveyor systems and is found in the majority of U.S. production facilities. According to the U.S. Dept. of Energy, 70% of all manufacturing facilities in the U.S. have some form of compressed energy.

Despite compressed air being “just air” it’s an expensive form of energy to use for two main reasons.

1. The way in which compressed air is created means about 90% of the generated energy is lost to heat — leaving only about 10% of energy is converted into usable compressed air.

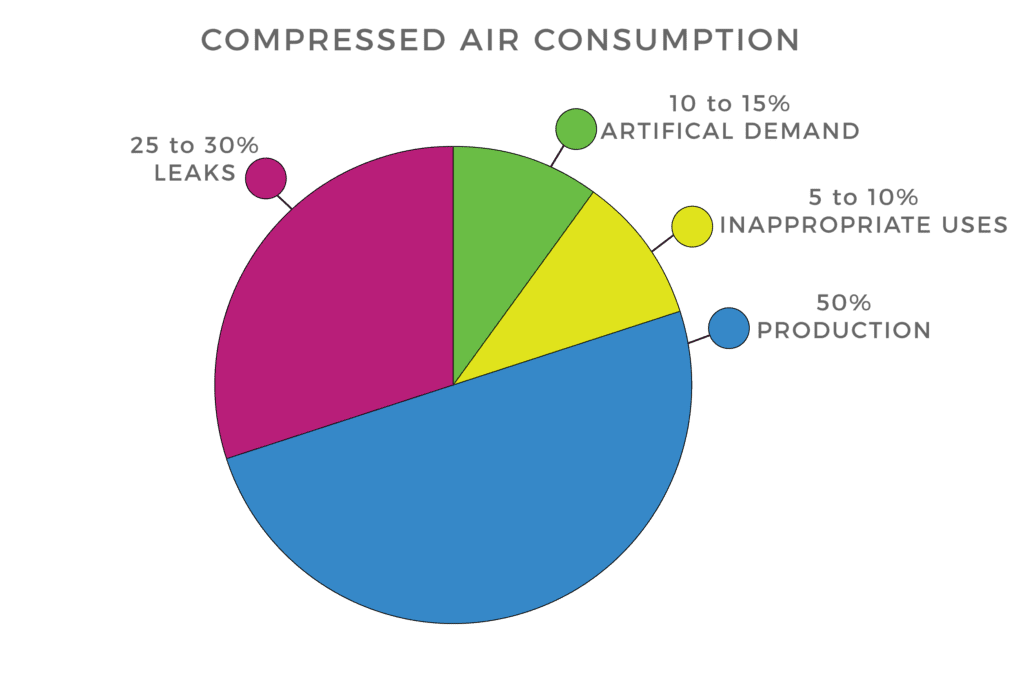

2. Compressed air is also expensive because only 50% of the air generated is actually consumed during production operation. That’s according to compressed-air dispensation data from the voluntary industry collaboration organization known as The Compressed Air Challenge.

In conveyor systems — specifically, pallet-handling conveyor systems — compressed air is typically used to power various pneumatic modules and accessories. These items include but are not limited to:

• Pallet stops

• Vertical transfer units

• Right angle transfer units

• Pallet locating devices

• Pallet rotation devices

These are the very devices that make pallet-handling conveyor systems as productive, streamlined, and versatile as they are known to be. Without these modules, pallets and thus product wouldn’t be able to transfer between conveyors, change travel direction, or move up and down between conveyor levels. Without these modules, pallets couldn’t be positively located for precision applications … nor could they be separated during accumulation.

As we’ve alluded though, these devices (which ultimately are what bring a conveyor system to life) are the very devices directly impacted by the inefficiencies of compressed air systems and related additional energy costs.

However, there is an alternative — all-electric pallet-handling conveyor systems.

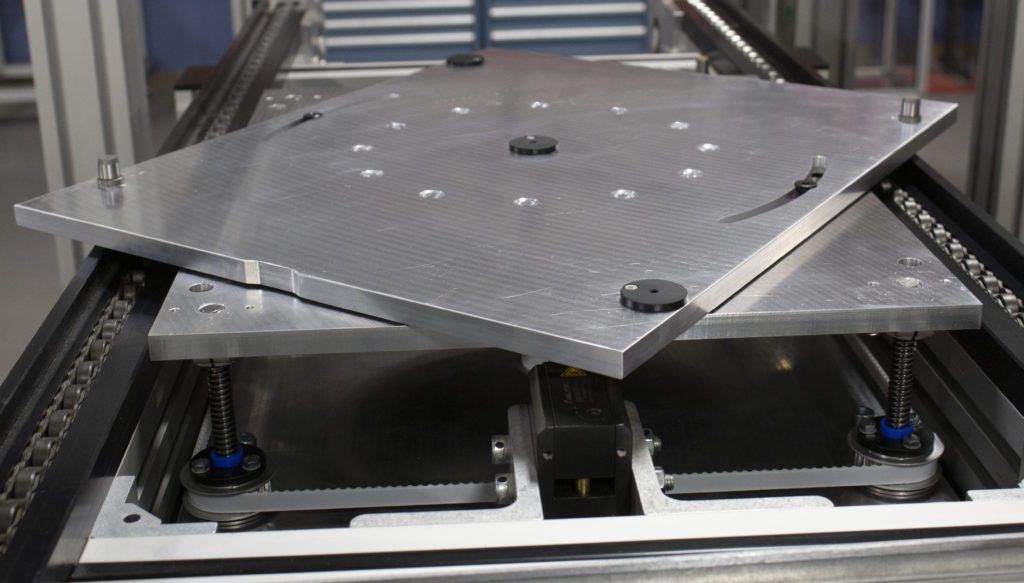

In all-electric pallet-handling conveyor systems, not only are the conveyors’ motors electric (as they traditionally are) but so are all the peripheral devices. Pneumatic stops are replaced with electric ones. Pneumatic actuators that provide vertical movement in the various transfer units are replaced with electric linear actuators or motor-driven timing-belt linear modules. Rotate devices are redesigned using timing belts and smart motors, or with rotary indexers.

It’s true that pallet-handling systems featuring electric modules may have a higher initial cost than traditional pneumatic platforms, but operational savings and benefits are not to be overlooked.

“Electric stops and transfers offer a wide range of advantages to control systems,” says Steve Sicard, an automation engineer for the machine-integration company Plastimation. Compared to their pneumatic counterparts, electric stops and transfers have higher precision and a wider range of controllability. Electric components are also a simpler solution … and in the long run, can really decrease the cost per part produced,” adds Sicard.

Electrical actuators offer the highest precision control for positioning in the industry. Some electrical positioning actuators boast an accuracy range of ±0.000315 in. with a repeatability of less than 0.0000394 in.

“Air can become a very expensive commodity in a manufacturing environment. Machines with a large number of pneumatic devices having the occasional air leak here and there make for hidden operational costs that can really add up,” adds Sicard.

Further cost savings with an all-electric system can also be found in the need for fewer system components. “With electric stops and transfers, you are able to negate any hardware related to pneumatics — including manifolds, air preparation systems, plumbing, and so on,” explains Sicard. “Plus, electric components allow direct feedback — in contrast with positional sensors for such feedback from pneumatics.”

This direct feedback is immediate and serves both diagnostic and maintenance purposes. Because of the speed in which feedback is received and how it works seamlessly with the system’s controls, downtime can be dramatically reduced. Additionally, less personnel may be required for troubleshooting, maintenance, and repair due to the direct feedback.

Lower component counts also mean faster and easier routine maintenance. Should something go wrong, troubleshooting is far simpler thanks to the direct feedback from the electric components already mentioned … and due to the fact that there’s no need to check auxiliary hardware (such as tubing, fittings, filters, and manifolds) to see if it’s the culprit.

The lack of this auxiliary hardware has additional benefits. Aside from the cost savings associated with not needing these items at start-up, there is no need to stock them for spare and replacements parts … which saves space at the end user’s facility.

Electric components are quiet — which makes facilities safer

Besides being a greener solution, pallet-handling conveyor systems employing electric instead of pneumatic modules are also a quieter solution. Pneumatic devices contribute to the overall noise pollution in a facility. Electric devices themselves operate at a lower volume than their pneumatic counterparts. In addition, they avoid the background hiss of compressed air. This background hiss is so commonplace that one often doesn’t realize how loud it is at the end user’s facility until it has stopped.

European companies have led the charge in adopting all-electric pallet-handling systems, because their environmental and noise regulations are much more pronounced. That’s according to Orlando Sanchez II, engineering manager for VersaMove of mk North America. “Our customers in the U.S. have been slower to adopt all-electric (E-only) systems,” he notes.

However, as the American consumer clamors for more eco-friendly products (that are also produced in eco-friendly ways) U.S. manufacturers will have the option to transition from traditional pneumatic-heavy pallet-handling systems to electrified systems.

Today’s highly competitive manufacturing sector demands conveyor systems that optimize material flow and keep workers safe. As mentioned, electrified pallet-handling systems are quieter than their pneumatic counterparts. According to the National Center for Biotechnology Information, 25% of current workers had a history of occupational noise exposure — with 14% exposed in the last year. In addition, 12% had hearing difficulty, 24% had hypertension, and 28% had elevated cholesterol … with 58%, 14%, and 9% of these cases attributable to occupational noise exposure, respectively. In addition, compressed air systems (while not the only noise factor in industrial and manufacturing spaces) are the most prevalent. The actual noise to which an employee is exposed depends on a wide variety of factors including but not limited to:

• The brand of air compressor used

• Where the employee usually works in relation to the compressor

• The quality and arrangement of the plumbing and devices, and

• How well the compressor is maintained.

These factors make it difficult to place exact values on the noise savings.

In conclusion, pallet-handling conveyor adoption continually increases with the exponentially growing need in the U.S. to optimize material flow. This combined with demands from customers for ecologically produced products (along with increased focus on worker safety) mean it’s no wonder certain conveyor manufacturers are offering and promoting all-electric solutions. “When the pneumatic devices are replaced with electrical ones, the overall result is a much cleaner and more reliable system,” summarizes Sicard.

mk North America | www.mknorthamerica.com

Leave a Reply

You must be logged in to post a comment.