The simple answer is yes. In fact, PC-based controllers have been doing condition monitoring for many years and it is only becoming more prevalent.

PC-based condition monitoring took off with the advent of falling prices of electronic computing power. As a result, PC-based condition monitoring has been getting better with improved computer technology, more powerful data analysis capabilities combined with more widespread adoption of PC-based controls throughout the industrial automation world.

Condition monitoring really has two parts; sensors and data analysis. Small, affordable sensors can monitor specific parameters on a machine such as accelerometers for measuring vibration or sensors that measure temperature or other important physical quantities. The data from these sensors helps to spot some type of imminent failure by, for instance, indicating parameter values outside of a normal range of operation. Early detection of problems leads to reduced costs as well as less downtime for machines and production lines.

A key part of condition monitoring is not only the acquisition of the data at the sensor level but conveying this information further on for processing. A boon to PC-based condition monitoring is the ready availability of high-speed industrial Ethernet-based networks.

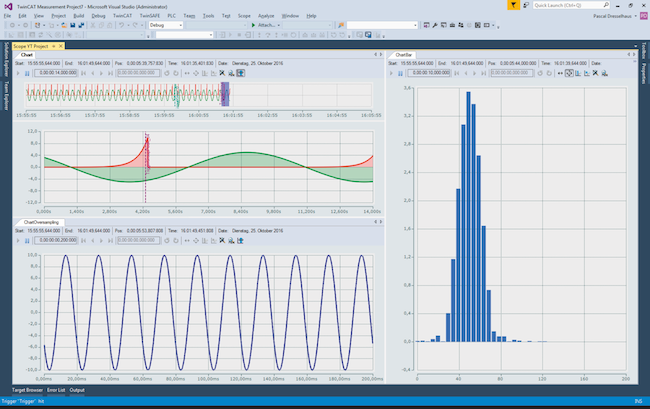

Condition monitoring relies on signal analysis. This is where the processing power of an industrial PC comes into play. Signal analysis using FFTs and other computation-heavy methods are easily handled on PCs, making them a natural choice.

Leave a Reply

You must be logged in to post a comment.