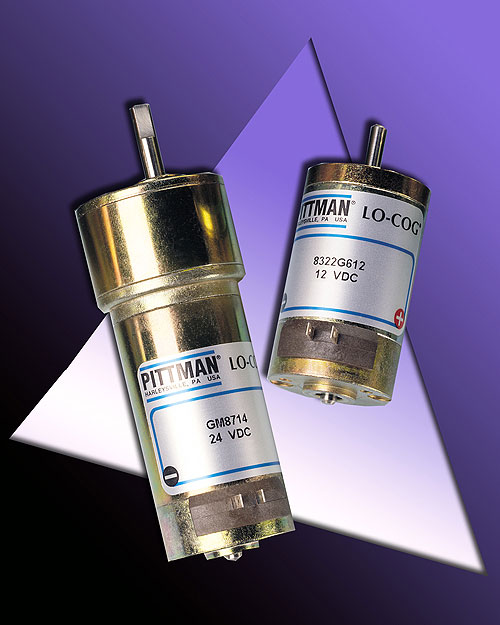

Pittman® “Series 8000” brush-commutated DC motors feature a 7-slot skewed armature design to minimize magnetic cogging (or reluctance torque) and promote smooth and quiet operation. This family of motors offers high performance and reliability to power applications ranging from data storage and medical equipment to semiconductor processing and automation machinery, among others.

These motors are available in three lengths (2.070 in., 2.195 in., and 2.445 in.) and can achieve peak torques up to 16.8 oz-in and speeds up to 9020 RPM at continuous torque for standard motors at rated voltages. Speed, voltage, current, and torque characteristics can be varied to satisfy particular application needs.

Standard features for all models include, 2-pole stator, neodymium magnets, heavy gauge steel housing, silicon steel laminations, and copper graphite brushes. Commutators are diamond turned after armature assembly to promote optimum concentricity and long brush life. Windings are resin-impregnated for greater reliability in incremental motion applications.

Modular construction enables their assemblies to be customized with alternative brush materials, optical encoders, timing belt pulleys, brakes, cables, connectors, modified shafts, and RFI suppression or other special configurations to meet application demands. Motors can be equipped with planetary or spur gearboxes as specified.

AMETEK Technical & Industrial Products

www.ametektechnicalproducts.com

Leave a Reply

You must be logged in to post a comment.