KENT, OH — Pittman® brand “I Series” brushless motors equip machine designers with a family of motor solutions created for commercial and light-industrial OEM applications. Motors are available in various sizes offering a wide range of performance capability from 40 Watts to 1700 Watts continuous. Brushless technology delivers extended service life, efficiency, improved performance, and superior machine control.

The I Series motors were developed using the latest magnetic tools and materials. Their magnetic core is optimized to favor power density and efficiency while minimizing cost. The winding system allows for a wide range of operation on machine bus voltages from 12 VDC to 325 VDC. The choice of materials, including bearings, Hall devices, and insulation promote extended service life.

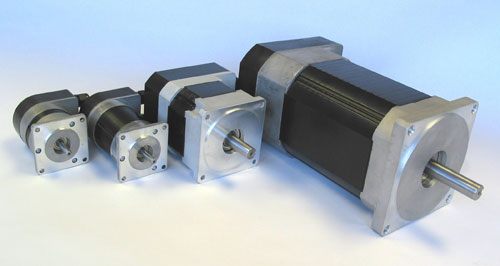

These small and powerful motors are available in NEMA frame sizes 17, 23, 34, and 56 and in multiple lengths for each. Depending on model, they can provide continuous stall torque from 0.117 Nm to 6.6 Nm (1 lb-in to 58 lb-in) and peak torque from 0.35 Nm to 19.7 Nm (3.1 lb-in to 174 lb-in). Rated speeds for this family of motors range from 3000 RPM to 12000 RPM.

AMETEK Technical & Industrial Products

www.ametektechnicalproducts.com

Leave a Reply

You must be logged in to post a comment.