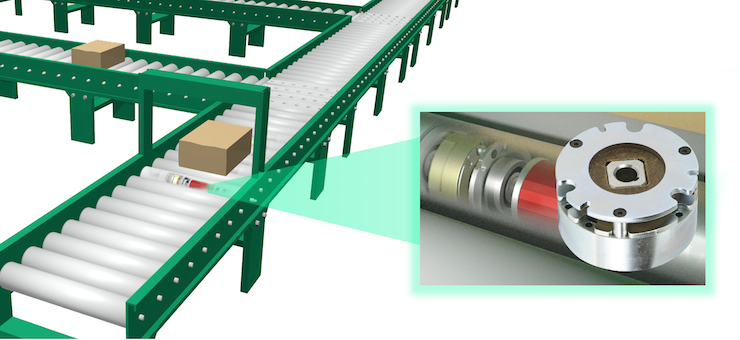

Miki Pulley’s latest model BXW power-off engaged brakes are designed to halt a motorized conveyor roller when system power is disengaged. These new BXW brakes are spring-actuated electromagnetic brakes. They provide reliable dynamic braking when conveyor power is disengaged and excellent performance for longer-term holding requirements for staging, loading and unloading conveyor operations.

BXW brakes use internal compression springs to provide power-off, fail-safe braking. The primary moving part in this robust but simple brake design is the armature plate. When actuated, the brake compression springs push the armature plate into the friction disc when power is disengaged. This feature provides fail-safe braking and allows the brake to maintain position over long periods of time, thus preventing a conveying system from “coasting” when powered off.

Another important feature is that the BXW brakes function at full torque rating “right out of the box” so no startup run-in is needed. They are available in three different models for either single use braking, holding or both braking and holding. Depending on size selected, BXW Brakes are suitable for small and large applications including use with servo motors.

Additional features include quiet operation, high holding torque, long service life, reliable braking power, and manual release mechanisms.

BXW brake specifications depending on model are:

- Brake torque 0.88 to 0.369 ft/lb (0.12 to 5.2 Nm)

- Brake outer diameter: 1.457 to 2.953 in. (37 to 75 mm)

- Ambient temperature: 14 to 104 °F (-10 to 40 °C)

For more information, visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.