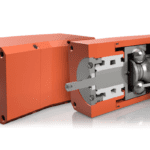

To upgrade machine performance or address stalling problems, manufacturers often resize motors with greater torque to reach greater accelerations for proper operations. Retrofitting a stepper motor, however, is time-consuming and expensive as it requires machining new mounting brackets and increasing the drive size and power supplies. PowerPlus Hybrid Stepper Motors from MOONS’ Industries eliminate the hassles of resizing motors by providing 25% to 40% more torque across the entire speed range of a motor. With the same physical dimensions as standard NEMA 23, 24 and 34 stepper motors, PowerPlus Hybrid Stepper Motors often drop into place to minimize upgrade costs while improving performance.

The increased torque of the PowerPlus technology is the result of higher motor efficiency. In a conventional stepper motor, some of the torque-producing flux that links the rotor to the stator is formed outside the stator teeth. The stray flux wastes power and adds little to motor torque.

The increased torque of the PowerPlus technology is the result of higher motor efficiency. In a conventional stepper motor, some of the torque-producing flux that links the rotor to the stator is formed outside the stator teeth. The stray flux wastes power and adds little to motor torque.

A higher magnetic flux density within the motor increases the performance of the PowerPlus Stepper Motor, enabling it to generate up to 40% more torque than conventional motors. Magnets placed between the stator teeth redirect and refocus most of the stray magnetic flux into the stator teeth to produce additional torque with the same input power.

Retrofitting existing motors with PowerPlus technology offers a quick path to producing new machines with improved performance.

Because the motor size, drive, and mechanical parts remain the same, PowerPlus Hybrid Stepper Motors:

- Reduce engineering costs

- Expedite new product introductions with an easier production phase

- Reduce spare parts inventory

- Provide a quick solution to stalling machines due to unexpected field conditions such as low temperature, dirt, wear of mechanical parts or lack of maintenance

Application for PowerPlus stepper motors

In a typical application upgrading stepper motor performance with PowerPlus technology, a manufacturer of CNC cutting systems wants to produce a high-performance version of its current machine to increase cutting speeds by 75% to 100% and improve move speed.

| Machine specs of current machine | Machine specs of high-performance machine |

| · Rapid move speed: 300 rpm

· Cutting speed: 150 rpm · Power supply output: 24 Vdc @ 5 A · Stepper drive output: 1.5 A · Motor holding toque: 210 oz-in. |

· Rapid move speed: 600 rpm

· Cutting speed: 300 rpm · Power supply output: 24 Vdc @ 5 A · Stepper drive output: 1.5 A · Motor holding toque: 330 oz-in. |

Engineering this new product, the CNC manufacturer wants to minimize engineering time while limiting parts inventory. A PowerPlus Stepper Motor provides twice the additional power over the existing motor needed for the new CNC machine without redesigning new parts or changing drives, power supply or the control program. In fact, by using PowerPlus motors, the machine builder can possibly use a smaller size motor and drive system to reach the same performance in a smaller and more cost-effective package.

For more information on the PowerPlus motors, visit moonsindustries.com/c/powerplus-hybrid-stepper-motors-a020102 or email chuck.leonard@moonsindustries.com.

MOONS’ Industries is a manufacturer of key components for motion control, intelligent LED lighting control, and industrial equipment management. MOONS’ cooperates with leading companies to provide creative solutions and high quality products focused on efficiency and performance. For more information, visit moonsindustries.com.

Leave a Reply

You must be logged in to post a comment.