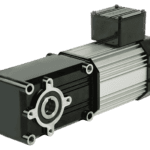

Bison Gear and Engineering designs and manufactures a complete line of standard and custom AC Right Angle Gearmotors and DC Right Angle Gearmotors. The gearmotors are used in applications such as industrial equipment, beverage dispensing, packaging equipment and conveyors. Bison’s line of right angle gearmotors provides the power and reliability to meet customers’ needs.

PMDC Right-angle gearmotors feature advanced precision hypoid gearing that delivers higher torque output in a smaller profile along with high-energy efficiency sustained throughout all 13 standard gear ratios. The PowerSTAR also features a sleek design that offers easy mounting in several orientations, ground gearing for low noise, and 712, 720, 725 and 730 frame sizes to fit a variety of design specifications.

It is available in 12V, 24V, 90V, 130V and 180V motor options. Certain frame sizes may not feature all voltages. Encoders are available but sold separately. For more information, visit this deep link at bisongear.com.

Leave a Reply

You must be logged in to post a comment.