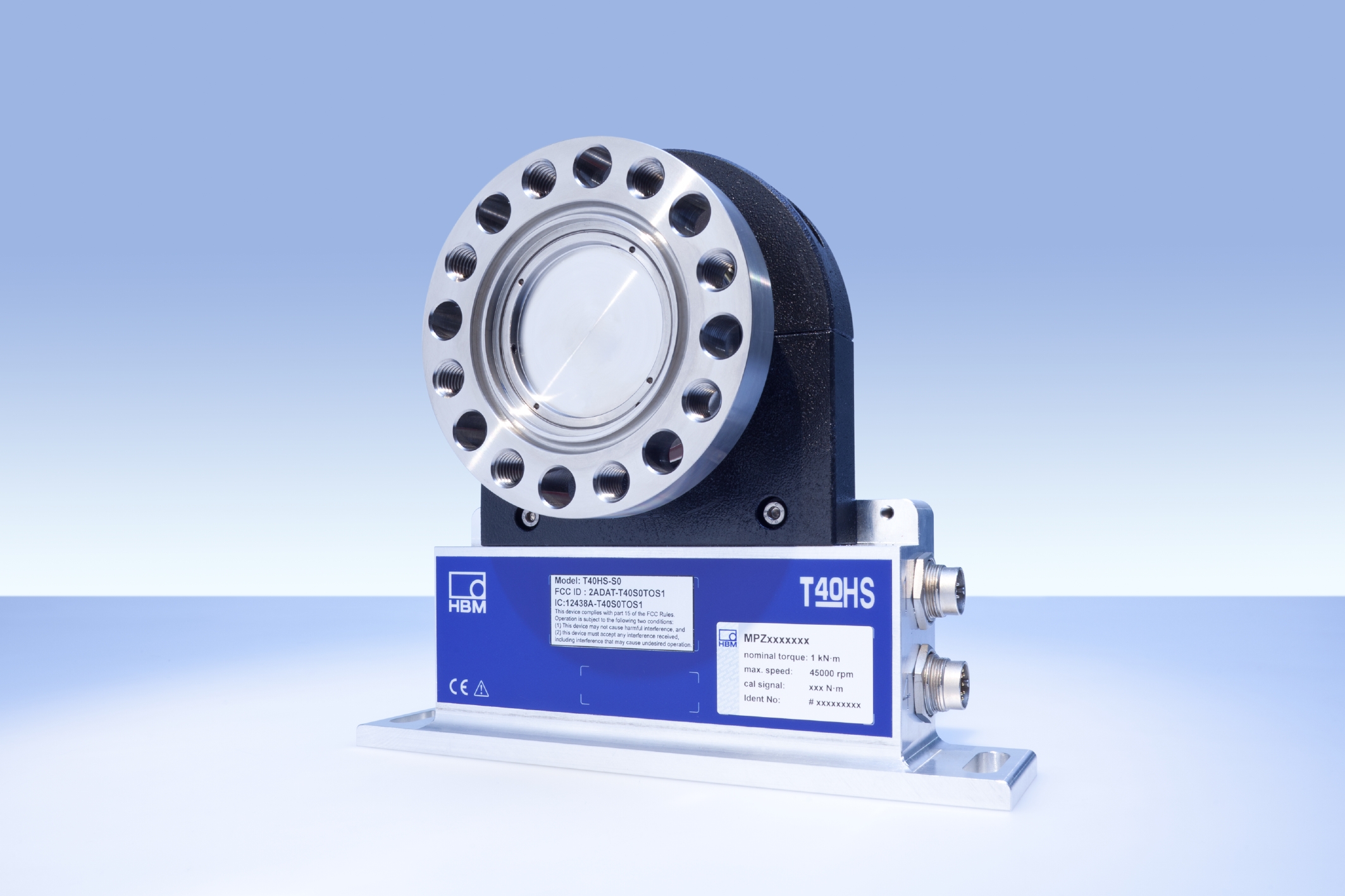

HBM Inc. now sells new compact T40HS torque transducers from HBM Test and Measurement.

The torque transducer is intended for measuring torque at high rotational speeds, offers high stiffness, is made of light titanium and ensures maximum precision.

Whether in motor sports or in the aerospace industry, performance tests of high-speed motors and drives at high rotational speeds are an important factor. Now HBM has developed the T40HS as a space and cost-saving torque flange for rotational speeds up to 45,000 rpm, for non-contacting transfer of signals while ensuring maximum precision.

Thanks to the compact measurement flange design, T40HS torque transducers feature high torsional stiffness, which allows for dynamic torque measurements. No additional bearings are required, which eliminates all maintenance overhead. The compact design of this torque transducer saves space, which makes it easy to integrate into a test bench, thereby cutting costs in the test bench design as well.

Torque transducers are compact, include titanium bodies

The use of titanium results in a low mass moment of inertia with a comparable design, which in turn reduces the dynamic torque in acceleration processes. Another advantage of using titanium is the relatively low weight of the T40HS. This reduces the load on the bearings of the drive machine, which extends the service life.

The T40HS high-speed torque transducer is used in such applications involving high-speed drives, turbines, transmission test rigs, adjustable actuators and for efficiency monitoring of complete power trains.

For more information, visit www.hbm.com or call (800) 578-4260. HBM Inc. is a leading manufacturer of data acquisition systems, analysis and calibration software, strain gauges, transducers and sensors.

Leave a Reply

You must be logged in to post a comment.