According to some, today’s most demanding motion designs either incorporate a PAC or industrial PC — and these are engineers’ two leading options for machine control right now.

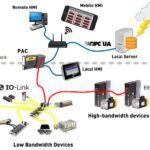

Recall that until recently, industrial automation (including motion control) was extremely segmented. So supervisory control and data acquisition (SCADA) systems were at the system top layer … separate from machine-level HMIs … in turn separate from PLCs on the machinery … with those oftentimes separate from devices reaching down to the motion control level — or at the end reaches of the machine executing other complex processes beyond the capabilities of a PLC.

In contrast, many of today’s automation systems blend motion control with robotics, vision systems, I/O, HMIs, at a single piece of hardware — the PAC. Some even connect to or serve as IoT gateways to allow communications with enterprise-level systems and the Cloud.

Of course, non-PAC solutions (employing PLCs and motion controls) remain the most suitable for a wide range of applications.

What’s the difference between today’s industrial PCs and PACs?

Consider that a PAC is at its core an industrial PC that’s running soft motion and a real-time operating system to handle the logic.

The most direct alternative to PACs are industrial PCs upon which engineers build their own applications. Even here, standardization is on the rise. For example, ROS-Industrial (the free open-source robotic operating system first begun by associated consortia in 2012) has recently added additional stacks to serve in more industrial applications. A large ROS-Industrial community provides professional support to prevent siloed design work and support controls engineers.

Insight from this FAQ derives from a recent chat with Marissa Tucker, product manager of controls and automation at Parker Hannifin about specifying controls based on standards rather than brands. For more information from Parker on PACs as well as free simulation software for trying out IEC 61131-3, visit parker.com/emn/pac.

Leave a Reply

You must be logged in to post a comment.