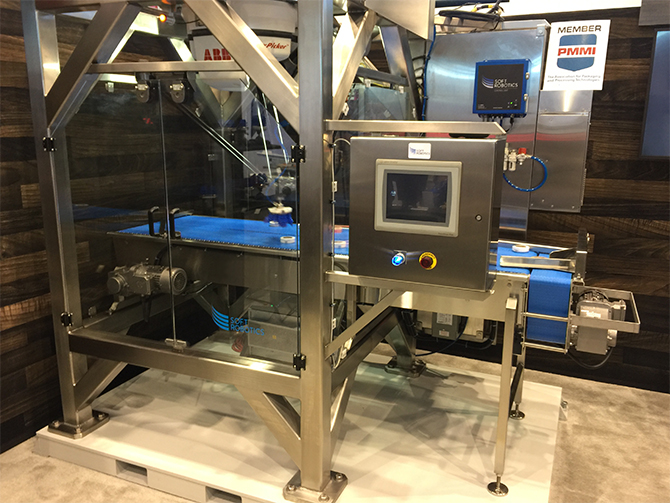

Just before the recent Pack Expo 2018 in Chicago, Soft Robotics Inc., manufacturer of soft robotic gripping and automation solutions, had a brand-new show-demonstration workcell go down. That prompted one of the company’s engineers to reach out to Encoder Products Co. exhibiting in another McCormick Place hall to get the demo working again.

“We had a last-minute issue with an encoder on a system we’d built specifically for Pack Expo,” said Soft Robotics application engineer Craig DeMello.“The day before the show, we had to replace that encoder. We needed a specific count — a very specific encoder — and Encoder Products Co. provided one that was programmable … and set it up for us to get the demo back to working in just a few hours.”

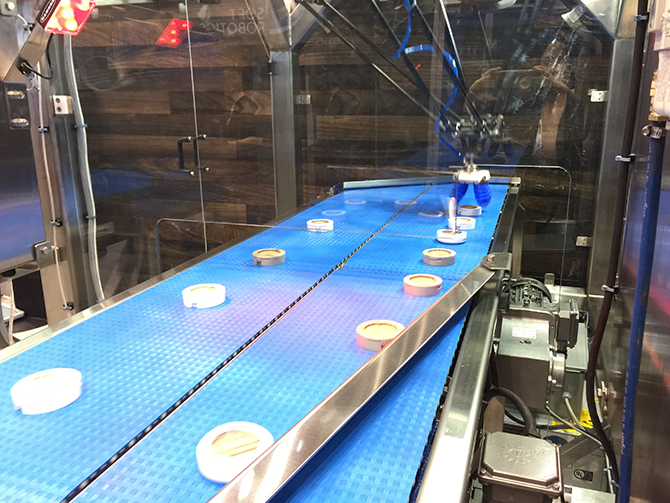

Within the demonstration cell, side-by-side conveyors run while a Soft Robotics gripper on an ABB FlexPicker quickly executes pick-and-place tasks from above. The gearmotor driving the demo’s front conveyor was the one needing a new encoder to work.

“The demo uses the FlexPicker and ABB’s picking software,” explained DeMello. “The encoder in question is on the belt from which the robot picks items … and the robot must keep track of each object — from the time the camera sees the object to the time it’s picked. That means it’s imperative that the robot knows where that product is when it goes to pick it — and the systems has to be very accurate.”

DeMello found Encoder Products Co. by going down the exhibitor list — and looking for one that might be able to help his team — with something he could buy that day.

“I contacted Tracey Howard with EPC, and it was really nice of him to help us out. His team was able to setup the counts and wiring on the new encoder for us very easily. In fact, all we had to do was change the mounting bore — that was it.”

The specific encoder supplied by Encoder Products Co. is a Model 25SP Accu-CoderPro programmable encoder.

“The programmable feature is why we were able to help Craig and the crew at Soft Robotics. With the millions of possible encoder configurations, it would’ve been unlikely we would have had an encoder to meet their needs without the ability to program the resolution, output type, and waveform,” said Howard.

Soft Robotics enables robotic automation for large markets and labor-starved industries such as food and beverage, advanced manufacturing, and e-commerce and retail. Leveraging patented material science and AI algorithms, Soft Robotics designs and builds automation solutions and soft robotic gripping systems that can grasp and manipulate items with the same dexterity of the human hand. For more information, visit www.softroboticsinc.com or www.encoder.com.

Leave a Reply

You must be logged in to post a comment.