MD&M West booth visit with Herrmann Ultrasonics to review the relevance of mechanical welding

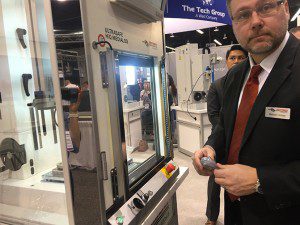

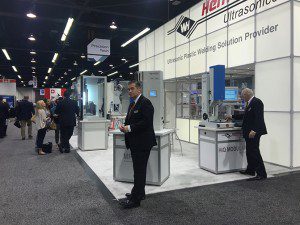

At my next stop, Cassandra Thibodeau and Michael Lindsay of Herrmann Ultrasonics reviewed the cost-effective and reliable approach to joining plastic components — ultrasonic welding.

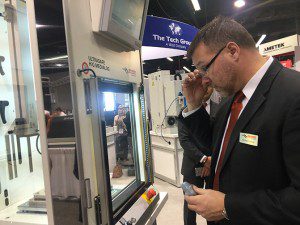

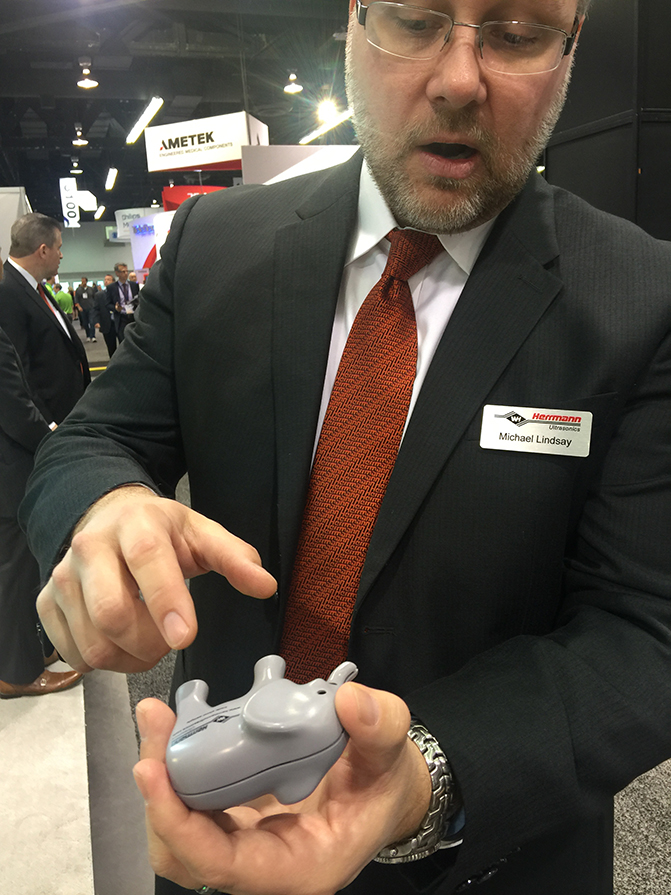

The toy-elephant-welding demonstration you see above and below here is one that Herrmann Ultrasonics featured at last year’s show, but what remains fascinating about the machine is all the exacting specifications that go into making a good part — making the joining edges of just the right geometry to mate and rub and melt together for a precision-engineered mechanism for joining.

Michael also explained to me how the rate and amplitude at which the Herrmann Ultrasonic machine vibrates the two halves of a part (to get a solid and verifiable weld) depends on the their material formulation. This is something that Christina Van De Walker and Udo Skarke explained to me in an overview the last time I visited, but I found this most recent visit to be an extremely helpful review to jog my memory. Expect to see more from Design World on this technology and company when we cover fastening and joining and medical applications.

Leave a Reply

You must be logged in to post a comment.