RESOLUTE true-absolute linear and rotary (angle) encoders with new compatibility for Siemens DRIVE-CLiQ will make their debut at the AMB international exhibition for metalworking in Stuttgart, 18th – 22nd September. DRIVE-CLiQ is the innovative, powerful communications interface to connect encoder and direct measurement systems with SINUMERIK and SINAMICS drive components. Allowing machine builders to achieve higher performance and greater reliability, this product conforms to Category 2 in accordance with EN ISO 13849 and so is suitable for use in safety-related axes such as linear motors and direct drive rotary (DDR) torque motors.

Outstanding performance

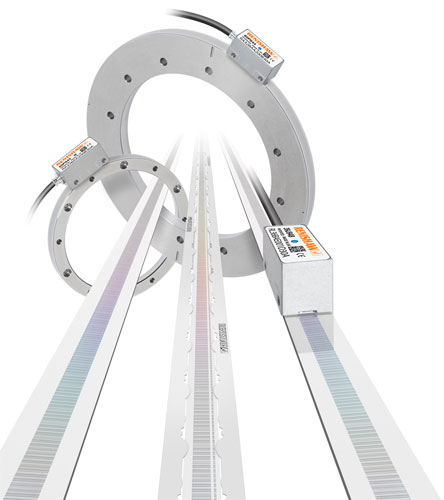

Visitors to hall 1, stand H72, will be able to see the outstanding motion control performance of RESOLUTE with the DRIVE-CLiQ interface. RESOLUTE’s unique operating principle is analogous to an ultra-high speed digital camera, capturing images of the scale, enabling resolutions up to 1 nm to be achieved (32 bit on rotary) even at speeds up to 100 m/s (36 000 rev/min on rotary). Advanced optics mean the detection scheme also has intrinsic low Sub-Divisional Error (SDE) and very low noise (jitter), so users can benefit from lower velocity ripple and rock-solid positional stability.

Such high-fidelity motion control performance is normally only associated with much more fragileRESOLUTE montage encoders, but RESOLUTE adds ruggedness and reliability, with sealed readheads and scales constructed from dependable shatter-proof engineering materials. The non-contact format eliminates bearings, seals, couplings and guideways from the encoder design, thereby also eliminating the most common causes of shock / vibration-induced encoder failure. Even if the main seals on the axis fail, RESOLUTE readheads are sealed against ingress of oil and coolant; simply wipe the readhead and scale, then start working again. Downtime is minimised and servicing /repair is simplified.

The non-contact format also helps improve system metrology. RESOLUTE rotary encoders read a solid stainless steel scale that is locked to the axis shaft so the encoder does not suffer from the mechanical backlash, wind-up and coupling losses that affect traditional enclosed encoders. Rotary scales include options with accuracy better than ±1 arc second, low-inertia versions and sizes from 52 mm to 550 mm, with custom sizes also available. Furthermore, the large through-hole allows the encoder to be mounted much closer to the point of interest without complicating the routing of services to payloads. The result is a system with greater dynamic capability, faster settling times and improved repeatability.

Linear encoders, with both stainless steel and ZeroMet™ (low expansion nickel-iron alloy) scales share many of these advantages, mounting direct to the machine’s structure or track guided. With precision-graduated unique single-track absolute code, linear scales include options with accuracy better than ±1 micron, or tape scales up to 10 metres long.

Functional safety

The functional design of RESOLUTE’s operating system paves the way for certification to EN ISOImage: Functional safety logo 13849, Category 2, performance level ‘d’. The detection scheme is inherently dependable, featuring advanced cross-checking and high levels of redundancy. Position is calculated every time the encoder receives a position request, so true absolute position is determined every time, meaning miscounting or ‘run-away’ is impossible. Safety is also enhanced by RESOLUTE’s unique built-in position checking algorithms. Each time the encoder receives a position request, RESOLUTE determines position using one algorithm, then verifies that result using an independent position checking algorithm. Any errors can therefore be flagged to the controller before the axis enters a dangerous condition. As a true-absolute encoder, RESOLUTE determines position immediately at switch-on, so complete control of the axis is achieved without any movement, reference returns or battery back-up. Proof of the effectiveness of these safety features is that RESOLUTE is being used in a variety of medical, defence and aerospace applications where reliability of position data is of primary and critical importance.

Quick and simple installation

For the machine builder, RESOLUTE offers a quick and simple installation experience. The scales are designed for easy installation, the readhead has large set-up tolerances and the readhead features a unique set-up LED that provides a very simple and intuitive indication of optimum installation. This LED (repeated on the remote DRIVE-CLiQ interface) provides simple diagnostics throughout the life of the encoder too, without the need for specialised set-up boxes.

RENISHAW

www.renishaw.com

Leave a Reply

You must be logged in to post a comment.