Miles Budimir

Senior Editor

Robotics is hot. Manufacturers in the business know this, and others are catching on. From investors to companies using more robots on the manufacturing floor, to consumers snapping up robots to do mundane house chores, robots are here to stay.

Industrial robots in particular are finding their way into new applications. And these aren’t the robots of yesterday, but nimbler and thus better able to handle some of the assembly tasks that were once the job of human workers.

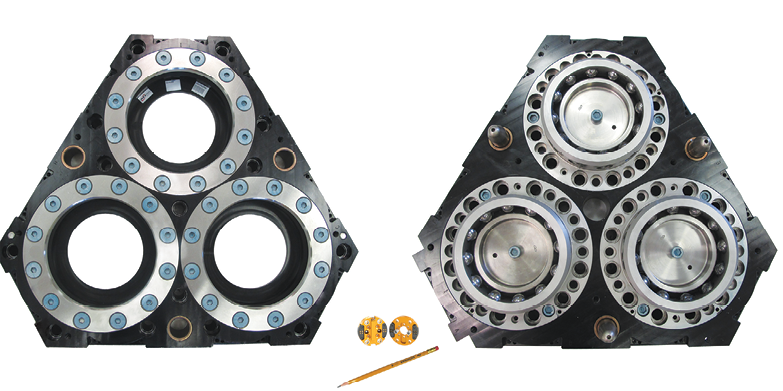

While industries like automotive manufacturing continue to be far and away the largest users of robots and robotic end effectors, other industries are catching on as well, noted Robert Little, CEO of ATI Industrial Automation. “A fast rising industry for robotic end effectors is consumer electronic assembly, such as mobile phone and computer manufacturing,” he said. “This type of manufacturing has been done by hand with cheap labor out of China. The volume is extremely high, but the parts are inexpensive so this is driving lower-cost end effectors.” In robotics and material handling, end effectors are tools or devices connected to the end of a robot arm that accomplish some task. End effectors can be a range of types, including cutting tools and drills, welding tools, brushes, screwdrivers, vacuum cups and grippers.

End effectors are one area where there has been much development over the past decade or so. As Little pointed out: “The sheer volume of robotic end effectors has quintupled from 10 years ago. Now we have a tool changer that can change out tools on very small spider robots and another tool changer that can assist with changing out multi-ton rockets.” The overall effect is more and better end effectors for a broader range of applications. “End effectors have increased their reliability and can be used in extreme environments like underwater, clean room, food handling and in space such as the Mars Rover,” he added. Another visible trend in robotics is the increase in robots designed to work closely with humans. Traditional factory-floor robots were often large pieces of moving metal that had to be enclosed in special cages with a plethora of safety features to keep human workers safe. Nowadays, robots are slimmer, nimbler and designed to work alongside humans. More robots in the workplace allow humans “to be moved from dull, dirty, delicate and dangerous tasks, into more stimulating jobs with far more potential for satisfaction and advancement, such as production management or robot programming,” said John Bubnikovich, VP, sales and marketing, ABB Robotics North America.

This trend toward more collaborative robots means that robots will become more commonplace in manufacturing settings. “Collaborative robotics and innovations that allow humans and robots to safely work side-by-side, like vision and advanced software technologies, can be deployed and programmed far more easily and rapidly than ever before,” added Bubnikovich.

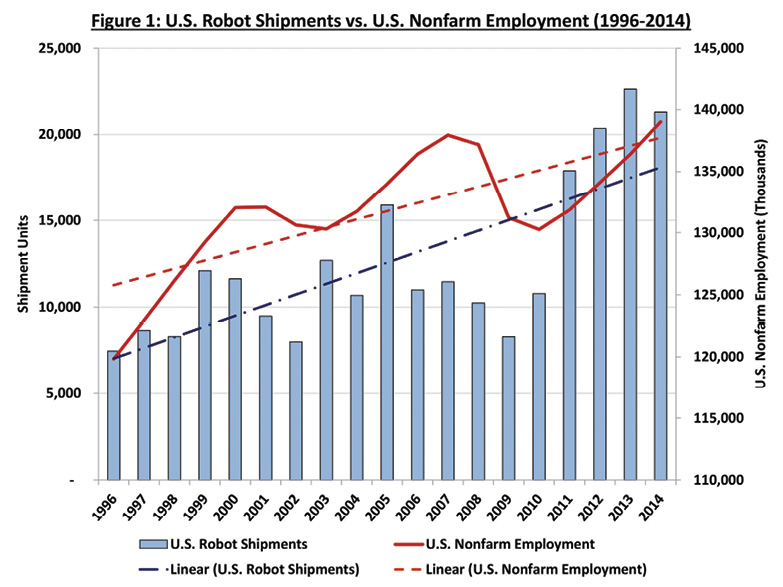

And while some analysts have raised concerns about the effects on employment as more robots enter the workspace, ABB sees the opposite effect. As Bubnikovich noted: “A study by Metra Martech concluded that the one million industrial robots currently in operation are directly responsible for the creation of close to three million jobs. The study further concluded that growth in robot use over the next five years will result in the creation of one million high-quality jobs around the world in prominent industries such as consumer electronics, food and beverage, alternative energy and advanced battery manufacturing.”

Leave a Reply

You must be logged in to post a comment.