If I had to make a list of the 2012 hot topics of the year in automation and motion control, energy efficiency would be high on that list. In fact, last month I wrote about some new tools from several automation suppliers aimed at improving energy efficiency of machines and motion systems. It turns out that energy efficiency is hot (sorry for the pun) not only at the systems or machine level but also at the circuit board level.

Case in point, recently ON Semiconductor released a new stepper motor driver IC, the LV8702V, that’s said to reduce power consumption and improve power efficiency in stepper motor controls.

As Tsutomu Shimazaki, general manager of power products for ON Semiconductor, explains: “The poor energy efficiency of stepper motors… has for some time been an area of concern… and a challenge to power system design engineers.” The company’s the new driver ICs improve energy efficiency and are said to have “… a unique driving system that enables it to achieve no-load power consumption savings of up to 80% and a reduction in peak motor current of approximately 77%.”

The LV8702V also helps reduce heat generation, vibration and noise from the motor in applications such as positioning control in printers. The surface temperature of the ICs and the motor are decreased by as much as 46C and 28C respectively, eliminating the need for separate cooling methods such as fans.

The LV8702V detects motor condition through drive waveform monitoring, and so power consumption is reduced by automatically reducing the current value according to the rotation speed or load of the motor.

For data sheets and a more detailed product overview, visit http://www.onsemi.com/PowerSolutions/product.do?id=LV8702V.

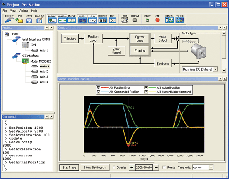

Scaling up from board level electronics hardware to the system perspective is news about a motion system design software package from Performance Motion Devices (PMD). The latest Version 4.5 of the company’s Pro-Motion software adds frequency-based servo analysis tools, an improved servo loop tuner, an easy to use axis setup wizard and compatibility with Windows 64 as well as Windows 32 operating systems.

The most significant new feature is the addition of frequency-based tools for machine and servo loop optimization. The software can determine mechanical response, servo loop performance, and system resonance. Users can select either a standard Bode plot or a frequency sweep, as well as sine wave, triangle wave, or square wave excitation waveforms.

Find out more about Pro-Motion 4.5, including access to a complete user’s guide, at www.pmdcorp.com/motion-control-software/.

Leave a Reply

You must be logged in to post a comment.