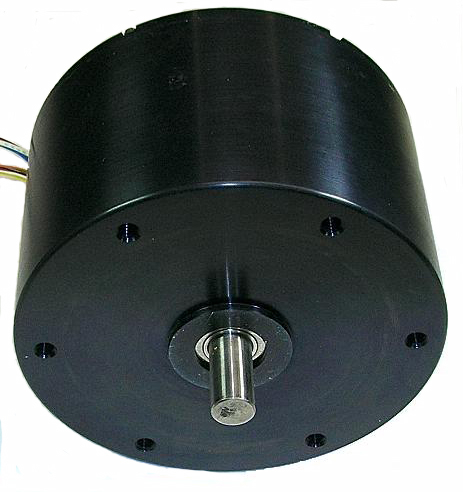

Koford Engineering offers a new line of 10-pole 5.07-in. (129 mm) brushless high performance motors with continuous stall torque up to 398 oz-in. with heat sink, and peak motor efficiency of 94%. The motor features low cogging for a slotted motor and a sinusoidal back emf for low torque ripple when used with sine drives. It uses 240°C ML wire insulation and high temperature thermosetting resin for the highest durability. The motor shaft is heat-treated stainless steel and the housing is machined and anodized aluminum. Standard speeds are 4,934 rpm and 2,436 rpm with input voltages of 48 and 24 V but custom windings can be provided.

The motor is available in either Hall or sensorless configurations. A version with advanced timing is available for unidirectional applications such as pumps and blowers, which improves performance at high loads. An encoder is available as an option and a compatible high-efficiency Hall drive can also be provided.

The motors are suitable for military, medical, aerospace, and industrial applications including servo positioning systems and also high torque applications in manufacturing equipment, pumps, blowers and other industrial applications.

For more information, visit www.koford.com.

Leave a Reply

You must be logged in to post a comment.