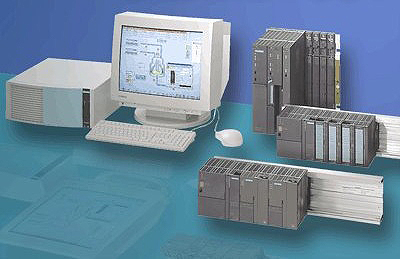

The Industry Automation Division of Siemens (www.usa.siemens.com/process) has equipped its Simatic PCS 7 process control system Version 8 with a host of new features, including an easier engineering workflow and improved data exchange.

It also offers more powerful communication, fault-tolerant and redundancy-related functions to its controllers as well as extended functionalities for the software tools.

In this latest version of the Simatic PCS 7, the data exchange between the PCS 7 engineering tools and the COMOS plant management software has been optimized while the engineering workflow was simplified. This provides users enhanced planning quality, and allows them to easily document the tracking of changes. Its built-in, scalable long-term archiving system, Process Historian, is now ideally suited for real time central archiving of process data from various projects.

Users can now quickly access reports and archive data for the purpose of enhancing assets and production. The standard Microsoft Reporting Service tool enables users to easily create and modify reports.

With regards to Profibus and Profinet communication, the PCS 7 Version 8 has also been improved in the areas of redundancy and fault tolerance, as well as for the controllers. The high-performance, fault-tolerant Simatic S7-400H controllers have been enhanced to offer not only new functions but greater performance as well. They feature an integrated two-port switch Profinet interface and an increased range of I/Os.

Meanwhile, the software tools’ functionality has also been extended in this version. The Simatic PDM has been supplemented with new export/import functions, while the Advanced Process Library now offers new blocks for starters and compact drives as well as motor management. In addition, its AdvES advanced engineering system now comes with an ISA 88 compliant concept.

Leave a Reply

You must be logged in to post a comment.