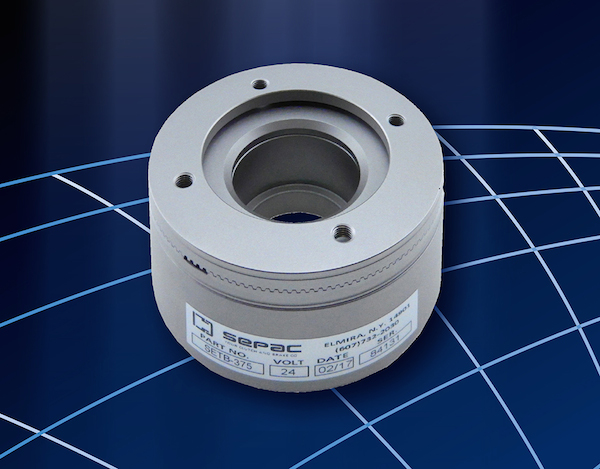

SEPAC designed the SETB electromagnetic spring-engaged tooth brake to deliver reliable, consistent operation within medical applications. This power off brake offers large bore sizes, low backlash, high torque-to-size ratio, a high number of index positions, positive engagement and a reliable coil with custom voltages available. These features, many not commercially available elsewhere in the marketplace, make it a top choice for medical applications such as robotics, scanning equipment, and treatment tables.

Features of the SETB include:

- Less than 0.5° of backlash within the brake once properly installed

- A high number of index positions

- High temperature Class H insulation fully potted coil rated for 180 °C

- Typically a 2:1 reduction in size when compared to a friction style brake with similar torque ratings

- Lead wires can also be routed through the bore or the rear of the magnet body

SEPAC frequently customizes SETBs and other product designs to fit OEM applications in the medical market and other industries. Custom bore sizes are available based on specific application requirements and each brake is virtually maintenance-free under proper operating conditions.

For more information, visit www.sepac.com.

Leave a Reply

You must be logged in to post a comment.