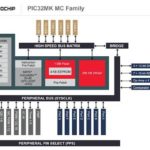

HEIDENHAIN CORPORATION announced that it is working with Texas Instruments (TI) in the development of the semiconductor industry’s first microcontroller (MCU) using the HEIDENHAIN EnDat 2.2 interface as an option. TI’s C2000TM MCU industrial drive control System-on-Chip (SoC) delivers a complete solution with a dir![]() ect connection for industrial motor and servo drives, supporting both analog and digital position sensors.

ect connection for industrial motor and servo drives, supporting both analog and digital position sensors.

When combined with TI’s DesignDRIVE Position Manager, this new solution eliminates the complexities of position sensor management in the industrial drive development cycle, saving ancillary components, development time and system cost. Common applications include use in industrial inverter and servo drives for robotics, CNCs, elevators, material conveyance, transportation, and other industrial manufacturing applications.

TI’s MCU system solution improves machine performance by completing decode tasks on-chip, reducing the communication latency and enabling faster control loop performance. It also allows developers to decrease system cost by reducing the board area required in FPGA or ASIC-based solutions.

TI is the only semiconductor vendor that supports both digital and analog position sensors for industrial applications. TI worked with HEIDENHAIN to test this on-chip solution to ensure compatibility. “We approve of TI’s successful implementation and testing of Position Manager to our EnDat specifications,” said Herbert Reiter, HEIDENHAIN’s Senior Product Manager, “and we look forward to working with TI as they enable new EnDat capabilities for our customers.”

HEIDENHAIN’s EnDat 2.2 interface is well known as a digital, bidirectional interface for encoders. It’s capable both of transmitting position values from incremental and absolute encoders as well as transmitting or updating information stored in the encoder, or saving new information.

For more information, visit www.ti.com and www.heidenhain.us.

Leave a Reply

You must be logged in to post a comment.