Encoders are central to motion control applications. They can provide position, speed, and direction feedback to a controller or drive to increase the accuracy and reliability of a drive system.

As technology evolves, so too do encoders, incorporating the latest advancements in communications and networking and offering engineers tools to solve challenges they face across a diverse array of motion control applications.

For example, Heidenhain has seen an increase in collaborative robotics and AGV robots driving the market, thanks to the focus on robotic Functional Safety. But also, new uses are coming into sight. Farming and agricultural applications are becoming more automated and as automation increases here, so too does the demand for reliable feedback of the kind offered by encoders.

Likewise, SIKO sees many of the same application demands from their customers as well, including robotic and farming but also the more established factory automation use as well as off-highway applications. The company sees requests for direct integration of sensors with high position accuracy that facilitates cost and space savings.

One driver of encoder trends is the IoT and the related industrial IoT. “The core of IIoT communication is to provide more insight into the machine by supporting communication from many different sensors,” notes Jonathan Dougherty, Business Development Manager of Automation Markets for Heidenhain. “We help to enable this functionality by taking in all the sensor functionality in and around motors (temperature sensors, accelerometers, magnetic field sensors, etc.) and transmitting that information back over a streamlined pre-established communication channel using the encoder communication,” adds Dougherty. The company’s EnDat interface handles these tasks all while cutting wiring costs and simplifying design.

Wireless connectivity is another part of communications equation. In Heidenhain’s case, the value they’ve seen in wireless connectivity is in providing easy access to diagnostic data to maintenance personnel throughout the factory floor. “Our Advanced Diagnostic System (ADS) Uptime functionality, from Leine Linde, provides relevant diagnostics, along with condition monitoring functionalities, to enable predictive maintenance and problem-free operation time,” says Dougherty. “And built-in Bluetooth condition monitoring makes it possible to pinpoint potential sources of failure before problems occur, just by walking through the plant,” he notes. Plus, the placement of the encoder on the motor or drive shaft makes it especially well suited to collect operational and environmental parameters like vibration and temperature variations. The encoders can then provide relevant information about potential sources of failure.

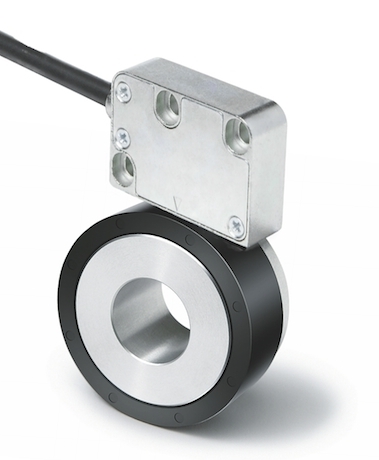

While technological changes to the encoders themselves are one thing, the way that engineers work and design is another. For instance, working more closely with end customers to solve their problems. “With SIKO MagLine focusing on the integration of its encoder technology into the application of the customers, several solutions were created according to customer demands,” notes Edward Stuart, MagLine Product Manager with SIKO. Stuart adds: “A good example are rotary applications such as torque motors. It’s necessary to adapt the magnetic scale on a ring that can be added to the rotor and also have the encoder element with custom specific housing or as an open PCB solution designed to fit perfectly in the limited housing space of the motor.”

Engineers are also sourcing more integrated designs. For instance, many manufacturers offer integrated motors that include controllers and encoders built into the motor. As Eric Rice of Applied Motion Products notes, “We’re now putting more of our development resources into feedback devices, such as small, high-resolution magnetic encoders and multi-turn, absolute encoders. The use of small, high-resolution magnetic encoders enables us to make smaller integrated motors for precision applications with light loads, such as medical and benchtop equipment.” The company is using multi-turn absolute encoders with no batteries or internal gears that offer a number of advantages. Once calibrated to the application, these motors with integrated encoders don’t need to reference a home position at every machine power up or changeover. “This makes them especially beneficial in applications where reference moves to a home position are time consuming, such as long-stroke linear applications and setup axes on packaging equipment,” adds Rice.

On the other hand, as Heidenhain’s Dougherty notes, “Most engineering is now done online before even speaking to a representative from any encoder company.” Which is why the company supports their customers’ research with tools that help engineers pinpoint the product they’re looking for and have a central source to access all the relevant information they need such as datasheets and CAD models.

Although again, with custom designs, it’s a bit different. As SIKO’s Stuart point out, “In general with the versatility of SIKO products we work directly with the customer rather than setting up tools for them to half design a product that we have to then go back and verify.” For SIKO, it seems to work better having their engineering departments work closely together from the outset.

Leave a Reply

You must be logged in to post a comment.