With high construction costs of rare earth permanent magnet synchronous servo motors, asynchronous (induction) motors are more acceptable, when possible.

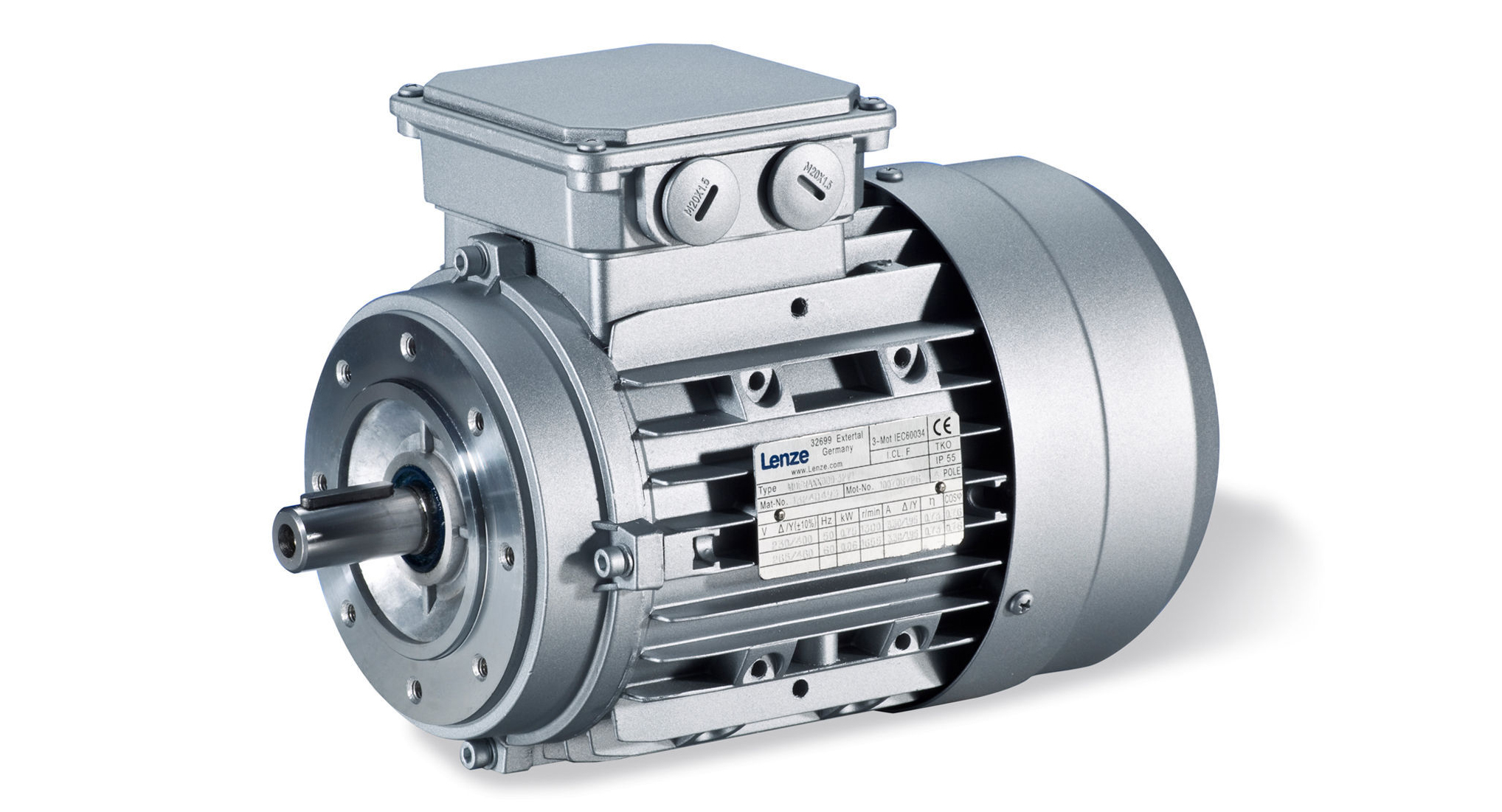

By Craig Dahlquist • Application Engineer at Lenze Americas

One way to get servo control of an asynchronous motor (on 400 to 480 Vac supply voltage) is to use a conventional 230/400 or 230/460 Vac (delta/wye connection) motor.

Typically, a delta connection is used for 230 Vac (50/60 Hz) across the line. But with an inverter, a 50 Hz motor with a 400 VAC supply voltage can control 230 Vac at 50 Hz.

As long as the correct Volts/Hz curve is followed, the motor can maximize power at 87 Hz.

The torque will also stay constant to 87 Hz before the motor goes into field weakening.

The math for this is simple: 400/230 · 50 Hz = 87 Hz. The calculations are the same for configuring 230/460 VAC, 60 Hz motors. Since the torque remains constant, the resulting power is equal to the motor power rating at 50 Hz · 1.732 (square root of 3). The rated current will also have a 1.732 factor compared to the 400 Vac rating in a Wye connection.

The result will be a motor capable of 73.2% more power from the same rotor inertia. A resolver is our most common feedback device. The resolver is robust (thanks to no wear parts) and is a single-turn absolute position device (for feedback on rotor-position angle).

The servo axis generally has to be accelerated and decelerated very dynamically for the application. Sometimes this is only possible with a permanent-magnet servo motor. When an asynchronous motor can meet the application specifications, generally the cost of the asynchronous motor is much less than the permanent magnet servo motor. Another reason for using the asynchronous servo or induction motor is to take advantage of the larger motor rotor inertia. When the application has a high inertia load, it may be necessary to get a lower inertia mismatch between the motor/geared motor and load. Also, in winding applications, the asynchronous motor offers a very deep field weakening range.

Winding applications are the main reason Lenze offers motors that have rated motor frequencies well below 50 or 60 Hz. This allows for the motor to run into field weakening earlier to better match the speed-torque curve of the winding application with the motor.

As in all designs, the application requirements determine the motor technology possibilities. In general, the next step is to determine the most cost effective solution for the application. Sometimes the asynchronous motor can be used in an application previously thought of as a permanent magnet servo motor application. Or, the asynchronous motor is the only choice for some applications.

Lenze has produced asynchronous servo motors for more than 25 years. The motors are specially designed for rated operating frequencies that are well above or below 50 or 60 Hertz. The induction motors are also specially designed to increase the power density of the motor. The motor ranges from 80 W (0.107 hp) to 60 kW (80 hp). The operating frequencies range between 20 to 140 Hertz. Motors that are not in the 50/60-Hertz range need to be connected by a general purpose or servo inverter.

Non-50/60 Hz motors cannot be connected directly across a three-phase 230 (0.080 to 0.6 kW) or 400/480 Vac main supply voltage.

Leave a Reply

You must be logged in to post a comment.