In a recent video with Lee Teschler, we investigated five air-engaged clutches from Mach III. The company designs and manufactures an array of air and spring-applied friction brakes and clutches — as well as mechanical torque limiters and combination clutch-brakes for industrial applications to 5,000 ft-lb. Watch the video:

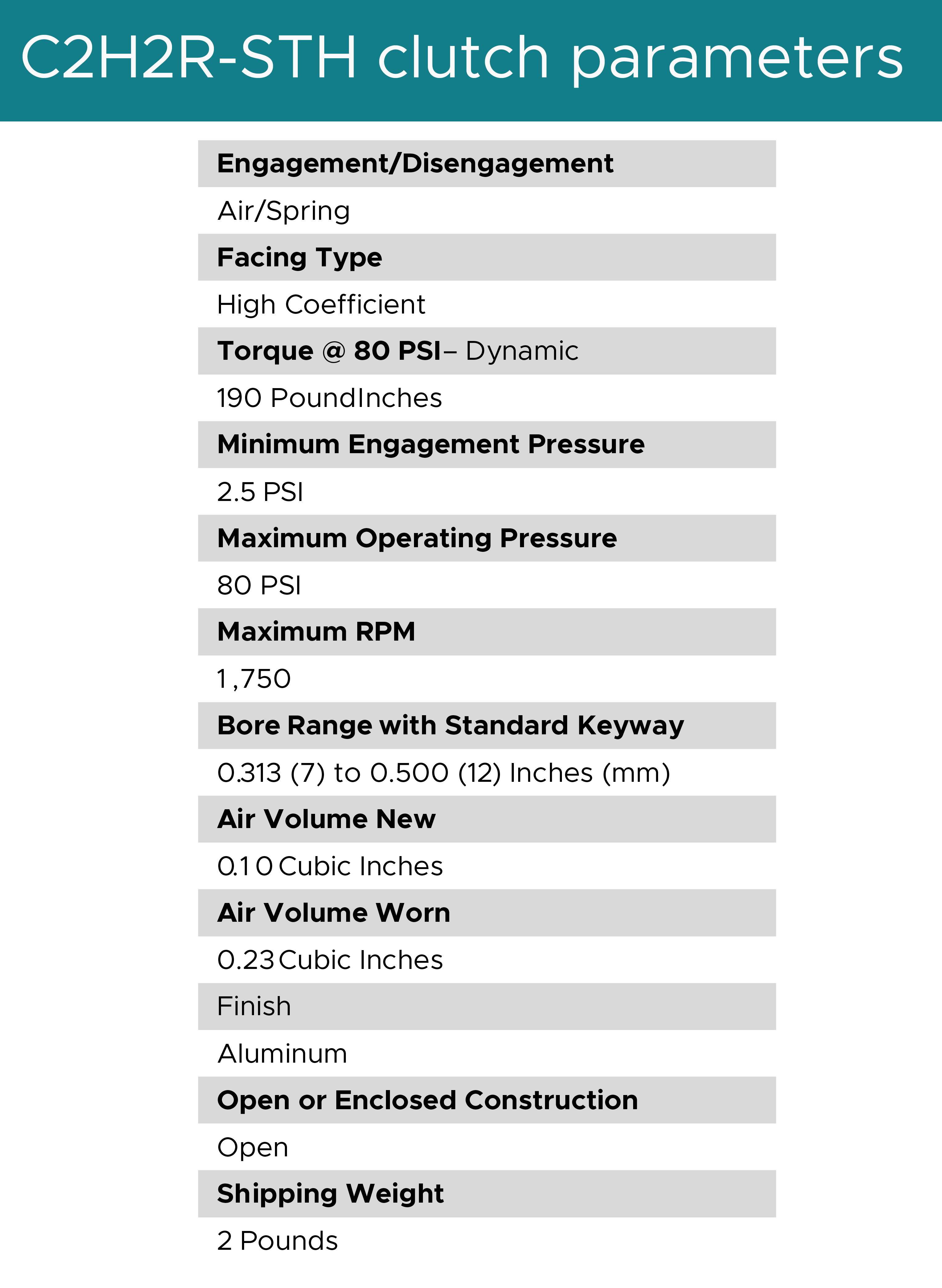

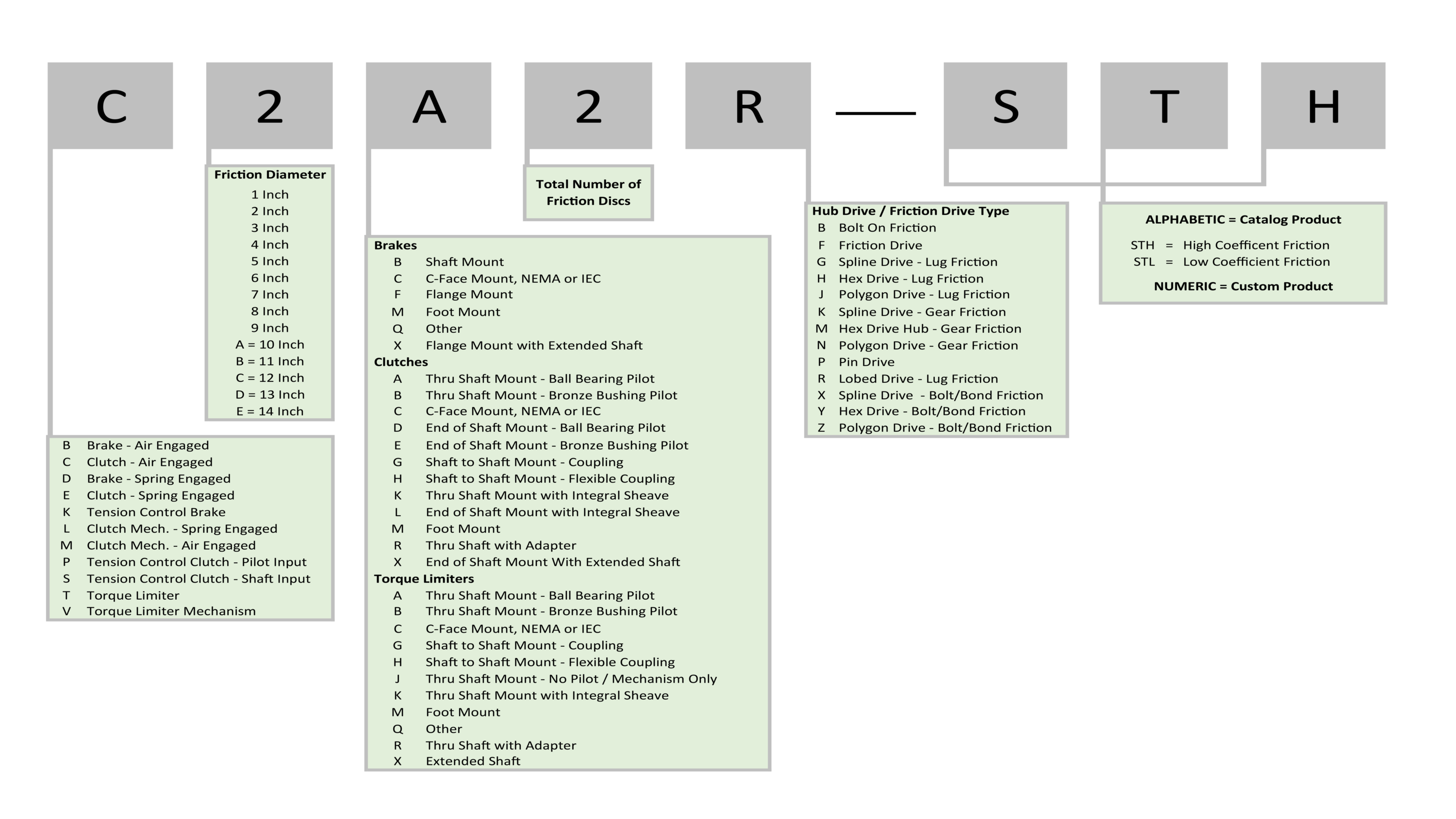

First we detail a C2H2R-STH air-engaged shaft-to-shaft flexible-coupling clutch. These friction clutches (as with all the other samples we detail in this video) engage with air pressure and then are spring released upon air exhaustion.

In this way, they connect and disconnect fully supported shaft pairs. An elastomeric element compensates for up to 3° of angular misalignment and up to 0.040 in. of parallel offset between shafts.

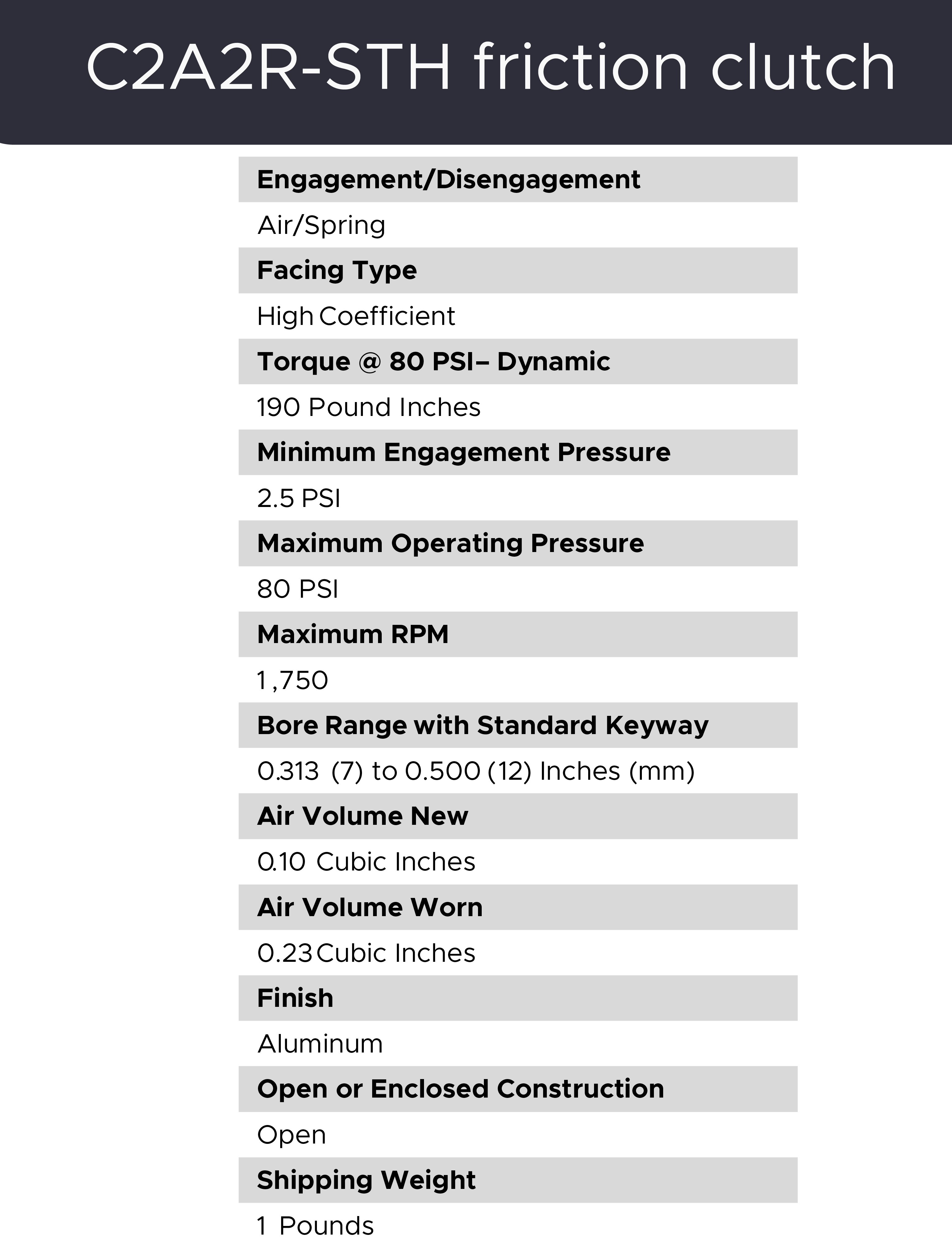

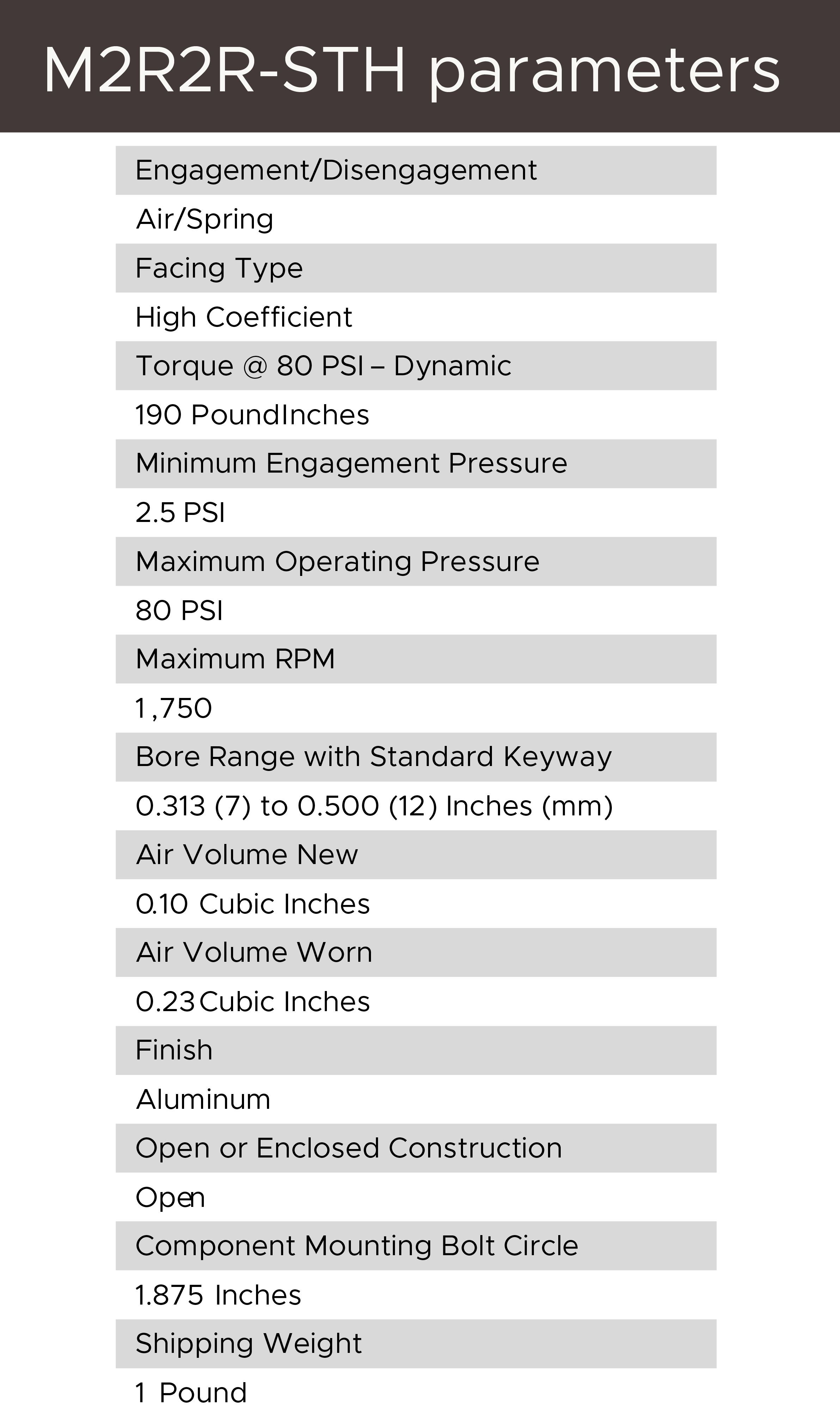

In contrast, a sprocket or pulley mounts on the pilot of the C2A2R-STH air-engaged clutch. This is a through-shaft-bored variation in a miniature-clutch line for torque requirements of less than 200 lb-in.

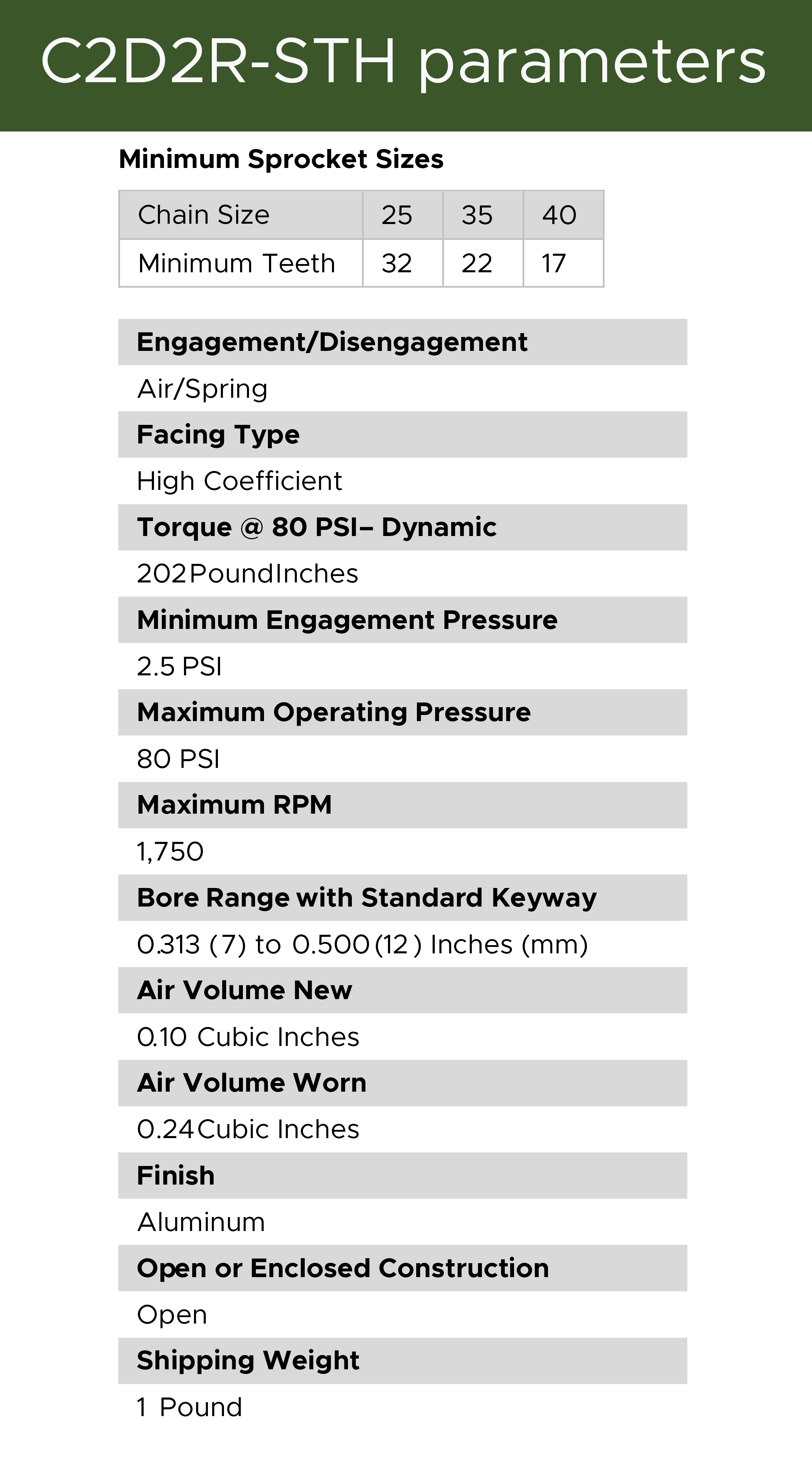

The C2D2R-STH air-engaged clutch we examine in the video is designed for end-of-shaft mounting … and for cycling and connect-disconnect applications.

It fixes to the shaft with setscrews or a customer-supplied key and includes a rotary air seal. Unlike the other clutches we consider in this video, this one does not need an anti-rotation arm to prevent rotation of the air housing.

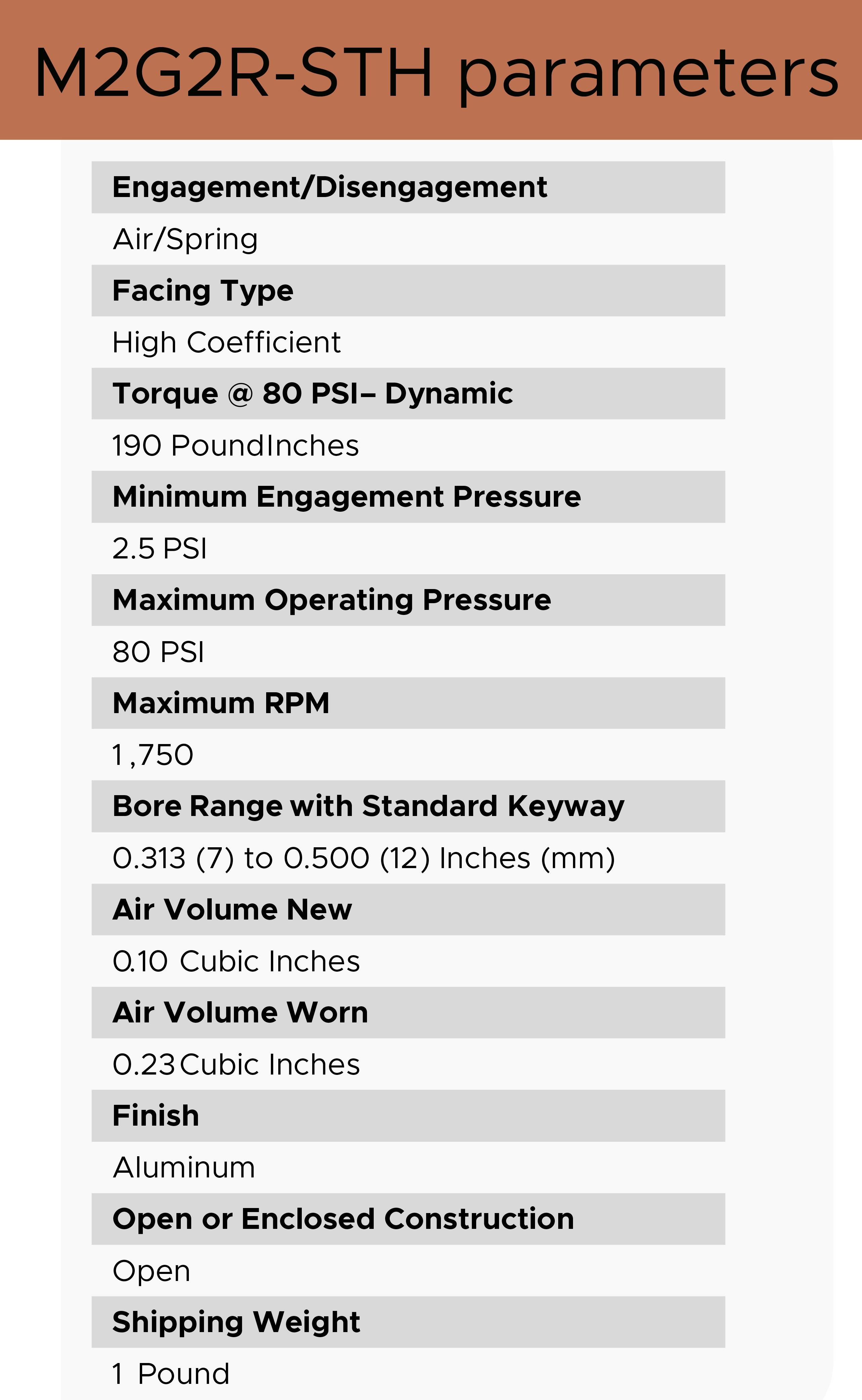

Next check out this M2G2R-STH air-engaged shaft-to-shaft rigid clutch coupling. It has a two-piece coupling body — with both the clutch mechanism and coupling half bored to accommodate differing shaft sizes.

Last but not least, we have an M2R2R-STH air-engaged clutch mechanism with adapter. Torque capacity is to 190 lb-in. As with the other clutches here, torque is linear in response to input air pressure. It’s also available with friction linings having a low or high coefficient for the same price. Linings with a low coefficient of friction are for designs needing a bit of slip or a narrow torque range.

These are just a tiny sample of what the manufacturer offers — in more than 2,000 standard models — though most of what Mach III supplies are slightly custom to very custom designs. In that regard, the manufacturer is somewhat ahead of a growing trend we see in industry. For more information, visit machiii.com.

Leave a Reply

You must be logged in to post a comment.