NORD DRIVESYSTEMS has developed modular, cost-effective smooth body gear units for washdown applications. This complete solution can tackle extreme, highly regulated environments, such as those within the food & beverage, dairy, pharmaceutical, chemical, car wash, wastewater, and marine industries.

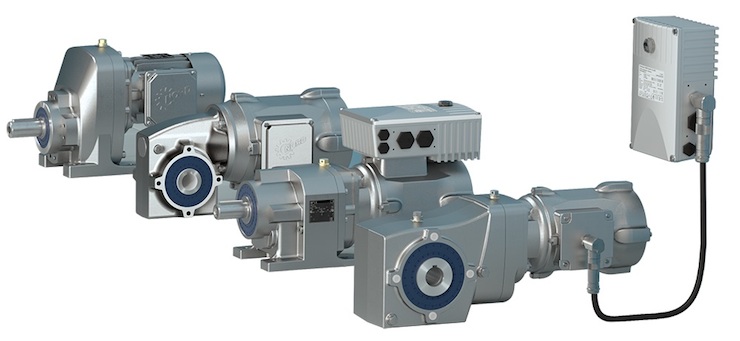

NORD smooth body gear units are available with IE3 efficiency motors in powers from 0.16 to 1.50 hp and IE4 efficiency motors in powers from 1 to 3 hp. These rugged units have a solid aluminum housing with Protection Class IP69K to resist corrosion and the internal gearing and shafts constructed from high- grade stainless steel. Smooth body gear units also have special shaft sealing rings and use food grade oil to comply with FDA food safety standards. Additionally, these motors have a wide range of available options, including brakes, encoders, thermostats, thermistors, space heaters, and other environmental protection options. NORD’s smooth gear units are available in many different configurations, including inline, right angle bevel, right angle worm, and parallel shaft.

On their own, NORD smooth body motors are durable, easy to clean, and resistant to corrosion and damage, but they are not limited to IP69K surface protection. Enter the nsd tupH sealed surface conversion system. This patented solution is not paint but a chromate-free chemical process that changes the physical properties of the aluminum housing, creating a surface that is 6 to 7 times harder than the original aluminum. After the process is complete, the housing receives an additional sealant that is resistant to contact corrosion from acids and alkalis (entire pH range), will not flake, and will not propagate damage when impacted or scratched.

Because of the unique properties of nsd tupH, NORD aluminum gear units, motors, and variable frequency drives treated with it perform comparably to traditional stainless steel units yet are much lighter and cost considerably less. In fact, units that go through the surface conversion process comply with FDA Title 21 CFR 175.300, a statute that outlines acceptable food-safe surface treatments and coatings. Additionally, nsd tupH has been put through rigorous testing via ASTM (blistering, corrosion, scratches, salt spray, and gravelometer tests) and DIN (salt mist spray and cross-cut tests). Results showed that nsd tupH fell well within acceptable ranges to meet these strict standards.

For more information visit www.nord.com.

Leave a Reply

You must be logged in to post a comment.