Precision-link conveyors index components with high accuracy, speed, and quality to give manufacturers a way to make assemble, mark, weld, and manufacturing operations more efficient.

Conveyor designs abound, and the last decade has brought more use of application-specific offerings — especially for the subcategory that industry calls transfer systems. One such conveyor is the precision-link conveyor — for assembly, marking, welding, as well as mechanical and optical inspection of parts. Standard precision-link conveyors deliver standard link-positioning accuracy of ±0.08 mm (±0.003 in.) or better.

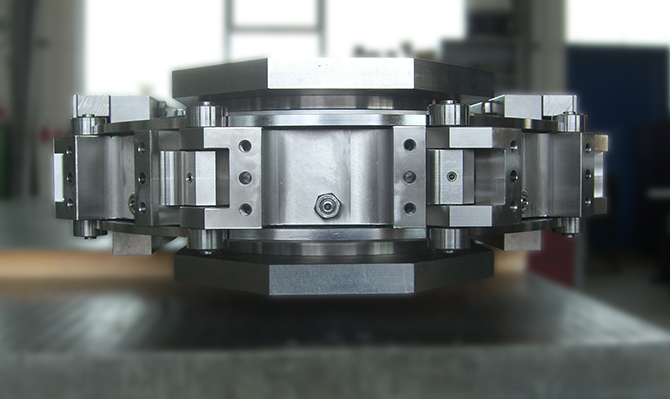

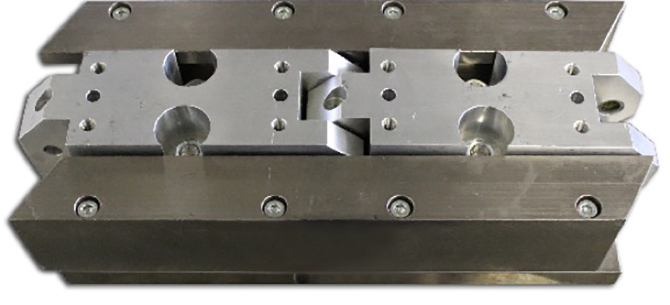

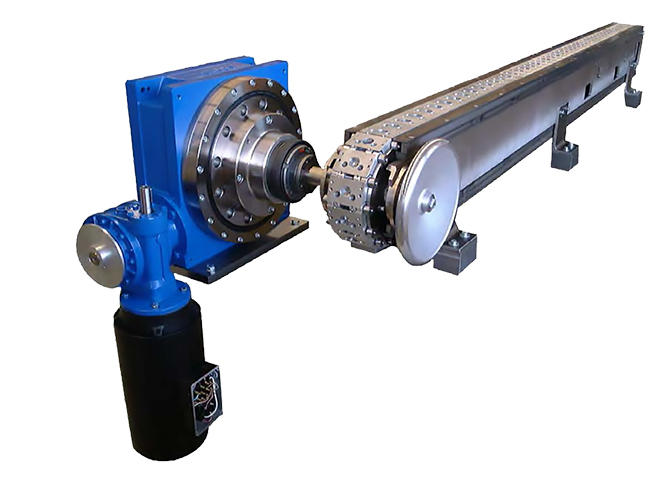

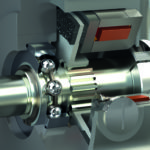

While there are belt-driven versions, many of these precision-link conveyors consist of one continuous run of high-precision drive chain. Then each chain link (often aluminum) contains four cam followers that guide the link along hardened and fine-milled guide rails. In some cases, the cam followers are sealed and lubed for life.

Dowels and bearings complete the chain assembly: The cam followers are pressed into needle bearings at the link joints to eliminate wear and prevent moving parts from contacting the links themselves.

Each chain link also includes tapped holes and dowel holes to accommodate individual pieces of product to be transported and otherwise machined or worked. Link fixtures can either interface with station tooling installed inboard or externally.

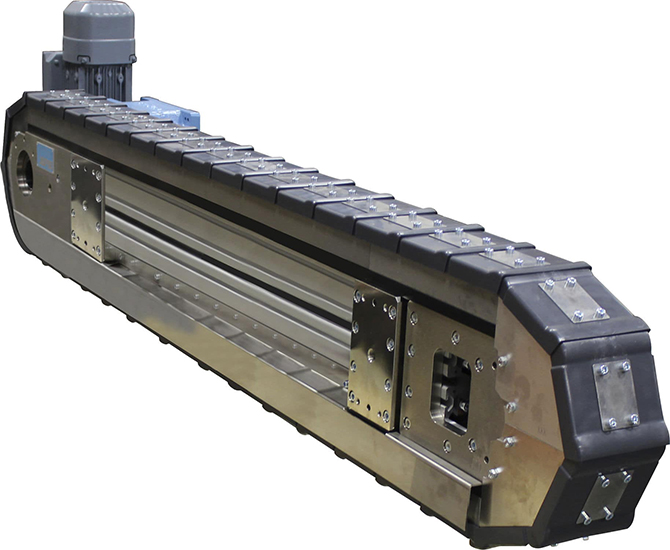

Typical precision-link conveyor frames are made of extruded aluminum frame and steel plates; the link track is machined, hardened, and ground steel. Some advantages of aluminum-extrusion frames is that they are very straight over long distances, are easily machined, and allow for easy mounting of accessories.

More on conveyor versions with aluminum components

Precision-link conveyors with an inner structure of aluminum extrusion offer distinct benefits. The extrusions allow long straight conveyor runs that maintain rigidity. Such structure also allows easy customization and mounting of accessories.

Links made of aircraft-grade aluminum also offer benefits. Aluminum links have a mass that’s a third of that of steel — for inertia that’s also a third that of steel links. That lets engineers use a smaller drive unit (whether index drive or high-accuracy gearmotor) or add heavier tooling without having to oversize the drive unit or compromise on indexing speeds.

Precision-link conveyor drives and customization

Driving the chain on a precision-link conveyor is either a customized drive based on a servomotor or the hardened cam wheel of a standard indexer. If the latter, one indexer cycle can spur any number of link stroke lengths … ranging from a few millimeters to a meter. No matter the drive, most precision-link conveyors are setup for long dwell times and quick indexing.

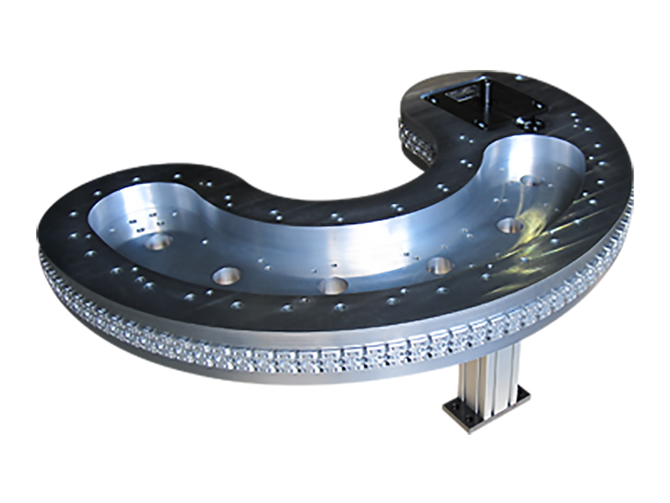

At the non-drive end of the conveyor circuit, a hardened and preloaded cam guides the chain and provides takeup to prevent backlash at the link connections. Common precision-link conveyor arrangements make runs that include two straight runs with 180° turns at the cam guide end and cam wheel end (if the drive is based on an indexer design). That said, variations include kidney-bean-shaped tracks, round tracks, and vertical variations — those that recirculate links with empty fixtures back to a start position on the underside of the conveyor as a way to minimize overall footprint.

Customized precision-link conveyors are manufactured to end-user requirements. With some manufacturers, nonstandard requests receive support beginning with the project design phase — for final conveyors that may include specialty drive units, tailored frame shapes, custom pitches and strokes, tapped holes, mounting plates, through holes in the chassis, and custom coatings on the components. Here, another option is custom link cover plates to prevent particulate ingress into the track and eliminate pinch points around curved conveyor ends.

Where precision-link conveyors excel

Precision-link indexing conveyors are most suitable for high-speed assembly of components — especially when there are high part counts or complicated assembly processes. Work processes are usually performed along the conveyor’s linear sections. Most useful for manufacturing tasks for aerospace, solar and wind energy, automotive, defense, electronics, consumer goods, and medical devices, precision-link conveyors are fast and accurate in positioning to allow assembly (and other tasks) on up to 150 parts per minute. That’s because whether driven by a servomotor or cam-controlled indexer, precision-link conveyors advance the fixtures precisely and without the need for additional positioning systems to locate fixtured parts before processes are initiated.

For example, these conveyors speed the manufacturing of dental floss and razor blades and other consumer goods with intricate assemblies. They also help make printing and marking applications faster (while maintaining image quality).

Typical precision-link conveyor operation

Precision-link conveyors allow automated processes right on the conveyor. After each indexed stroke (to advance the links) equipment mounted around the conveyor executes parallel and serial tasks. Most installations include multiple work stations along one or both long conveyor axes.

So unfinished products are mounted to the conveyor one time and then removed from the end of the conveyor — usually as completed product. In other words, precision-link conveyors are usually designed and engineered to be core product-positioning chassis of machines executing critical functions.

Precision link conveyors are designed to run high-volume manufacturing to millions of cycles without intensive maintenance. Typical maintenance involves tension checks and adjustments of the chain … and cleaning of the conveyor if it runs in a dirty environment.

Precision-link conveyors are unsuitable for feeding parts to a line, where a process is not being done on them. This is because their accuracy is not required. Similarly, due to their cost, they’re also inappropriate where application accuracy isn’t critical.

Information provided by Marc Halliburton • engineering manager | Motion Index Drives Inc.

Leave a Reply

You must be logged in to post a comment.