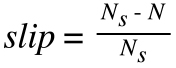

One of the fundamental characteristics of an AC induction motor is that the rotor spins at a slower rate than that of the stator’s rotating magnetic field. This difference in speed between the rotor and the stator’s magnetic field is known as slip.

Slip allows the motor to produce torque — the higher the slip, the higher the torque production, but also, the lower the motor’s efficiency (in most cases). But in load-sharing applications, motor slip can be used to prevent one motor from taking a disproportionate share of the load.

Ns = synchronous speed (rpm)

N = rotor speed (rpm)

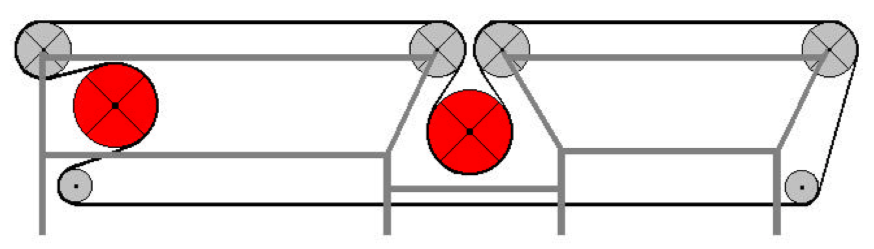

Load-sharing, in this context, refers to two or more AC motors connected to and driving the same load. Theoretically, each motor in a load-sharing set-up would experience an equal percentage of the load. But in real-world applications, numerous factors, such as variations in load along the length of a conveyor, or inconsistencies in the driven process, can cause the load to be distributed unevenly among the motors.

“Natural” load balancing

Because slip is inherent in AC motors, when two or more motors are connected to one drive, their natural slip will work to achieve balanced load sharing. As one motor experiences increased load, its speed (i.e. rotor speed) slows down, increasing slip between the rotor and stator. The second (and subsequent) motors, which are connected to the same drive, will also slow, allowing them to take on the additional load. While using the motors’ natural slip is a simple method of load-sharing, it is very imprecise and not reliable at high loads.

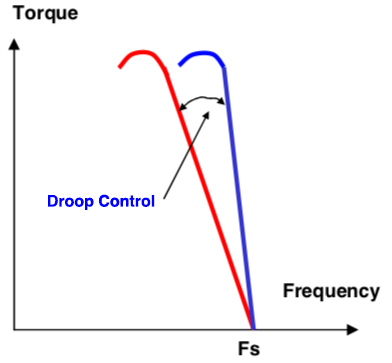

Droop control

For applications where load-sharing needs to be precise and controllable, some AC drives include a function — typically referred to as droop control — that manipulates motor slip to better ensure equal load-sharing. Here’s how it works:

Image credit: Schneider Electric

The drive monitors the motor torque (via current draw), and if the torque increases beyond a set value (indicating that the motor is taking on too much load), the droop control function decreases the output frequency of the drive.

The rotor speed has slowed due to the increased load, and the decreased output frequency from the drive causes the stator magnetic field to also decrease in speed. Hence, there’s a smaller difference between stator speed and rotor speed. In other words, slip is reduced, which reduces the motor’s torque production, allowing other motors to take more of the load.

Droop control can work both ways — reducing the output frequency of the drive when the load increases (to decrease the amount of load on an overloaded motor), or increasing the output frequency of the driven when the load decreases (to increase the amount of load on a non-drooping motor). This two-way method of controlling load sharing is sometimes referred to as “bipolar” droop control.

Image credit: Rockwell International Corporation

Leave a Reply

You must be logged in to post a comment.