When an electrical device, such as an AC induction motor, is switched on, it experiences a very high, momentary surge of current, referred to as inrush current.

When an AC induction motor is started, the supplied voltage creates a magnetic field in the stator, which induces a magnetic field in the rotor. The interaction of these two magnetic fields produces torque and causes the motor to turn. According to Lenz’s Law, the creation of the magnetic field causes an induced voltage, which opposes the supply voltage. This opposing, induced voltage — known as back EMF — also works to limit the amount of current in the motor.

However, the amount of back EMF produced is directly proportional to the speed of the motor. So at startup — when the motor speed is near zero — there is very little back EMF, and high “inrush” current is allowed to flow.

The amount of current drawn by the motor during startup is also influenced by the resistance of the stator windings. Newer, high-efficiency motors — such as IE3 premium efficiency versions — have lower winding resistance (to reduce I2R losses), so inrush current can be an even more significant problem in these designs than in older, lower-efficiency motors.

The highest level of inrush current occurs during the first half-cycle of motor operation and can be more than 10 times the motor’s full-load current. As the motor beings to move, the current decreases to the level of the motor’s locked rotor current, which is often six to eight times the motor’s normal operating current. As the motor speed — and, therefore, back EMF — increases, the current further decreases, until normal operating speed and normal operating current are reached.

Image credit: Electrical Engineering Portal

Locked rotor current is the current a motor will draw when the rotor is blocked or has not yet started to move. The terms “inrush current” and “locked rotor current” are often used interchangeably, but depending on the context, they can refer to different phenomena.

The U.S. Department of Energy explains the difference between inrush current and locked rotor current this way:

“Instantaneous peak inrush current is a momentary current transient that occurs immediately (within half an AC cycle) after contact closure. Locked rotor current is the root-mean-square (RMS) current that is established following the peak inrush; the current remains near the locked rotor value during acceleration until the motor approaches its operating speed. The terms inrush current and starting current are often used to mean locked rotor current.”

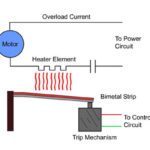

High inrush current can cause nuisance tripping of protective devices or motor damage. It can also cause voltage dips in the supply line (which can affect other equipment), or even prevent the motor from starting properly. High inrush current also leads to high torque production at startup — sometimes as much as twice the rated torque — which can cause sudden, severe acceleration that damages mechanical loads.

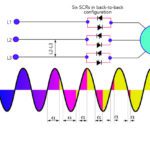

There are a number of starting methods that can reduce the inrush current levels in AC induction motors. One is to use a soft starter — a device that gradually increases supply voltage to the motor terminals during startup, thus lowering inrush current and controlling startup torque.

Similarly, a variable frequency drive reduces inrush current by controlling the voltage supplied to the motor. But a VFD works by varying the frequency of the voltage, rather than the amount of voltage, to the motor.

Leave a Reply

You must be logged in to post a comment.