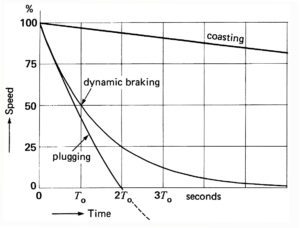

There are generally three types of electrical braking for motors: regenerative braking, dynamic braking, and plugging. Of the three methods, plugging provides the fastest stop, but it can be harsh on both the electrical and mechanical components. Because of this, it’s the least commonly used method of braking, but it is appropriate for some applications.

Image credit: secs.oakland.edu

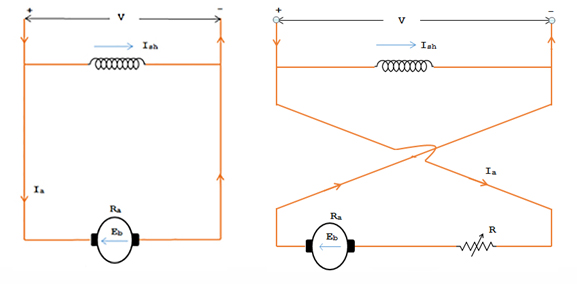

Plugging — sometimes referred to as “reverse current braking” — is possible on both DC motors and AC induction motors. For DC motors, plugging is achieved by reversing the polarity of the armature voltage. When this happens, the back EMF voltage no longer opposes the supply voltage. Instead, the back EMF and the supply voltage work in the same direction, opposing the motor’s rotation and causing it to come to a near-instant stop. The reverse current produced by the combined supply voltage and back EMF is extremely high, so resistance is placed in the circuit to limit the current.

For AC induction motors, the stator voltage is reversed by interchanging any two of the supply leads. The field then rotates in the opposite direction and the motor’s slip (the difference between the speed of the stator’s rotating magnetic field and the speed of the rotor) becomes greater than unity (s > 1). In other words, the rotor spins faster than the rotating magnetic field in the stator. Torque is developed in the opposite direction of the motor’s rotation, which produces a strong braking effect.

Slip, which is the difference between the speed of the stator’s rotating magnetic field and the speed of the rotor, is a fundamental property of AC induction motors. In normal motoring operation, the rotor spins at a slower rate than that of the stator’s rotating magnetic field.

When the motor speed reaches zero, if it is not disconnected from the supply, it will begin to reverse, or rotate in the opposite direction. In some applications, reversal of the motor’s direction is the goal. But when plugging is used to brake the motor, a zero-speed switch or plugging contactor is used to disconnect the motor from the supply when its speed reaches zero.

One of the potential problems with plugging as a braking method (especially when the braking time is short) is that it can be difficult to brake the motor at exactly zero speed. Another drawback to plugging is that it can induce high mechanical shock loads on the motor and connected equipment, due to the abrupt stop that it causes. Plugging is also a very inefficient method of stopping and, therefore, generates significant heat.

Despite these drawbacks, plugging is used in equipment such as elevators, cranes, presses, and mills, where a rapid stop of the motor (with or without reversal) is required.

Leave a Reply

You must be logged in to post a comment.