When a motor’s rotor speed is greater than its synchronous, or designated, speed, it can act as a generator, creating electrical energy from mechanical energy. This electrical energy needs somewhere to go, and there are two ways to deal with it — dissipate it as heat, or reuse it.

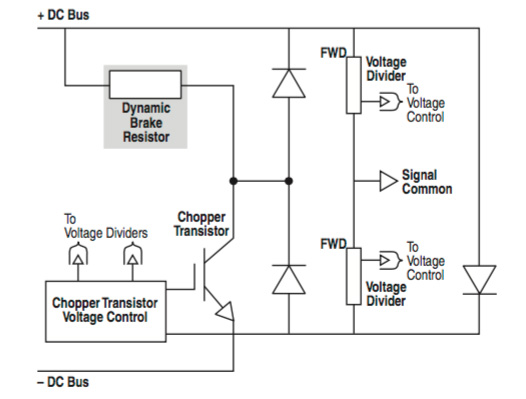

Dynamic braking takes the energy generated by the motor and releases it as heat through a voltage-regulated IGBT (insulated-gate bipolar transistor) to a resistor. In some applications, one or multiple resistors are mounted remotely, where the heat they generate does not affect other electrical equipment. In these cases, the combination of the switching devices (IGBTs) and the control circuit is typically referred to as a “chopper module.” Traditional dynamic braking circuits are rated for low duty cycles — typically 20 percent or less — while chopper circuits are used for higher duty cycles.

Image credit: Rockwell Automation, Inc.

There are two common control methods for dynamic braking — hysteresis control and pulse-width modulation (PWM) control. Hysteresis control monitors the level of DC bus voltage and turns the IGBT on when the voltage reaches a predefined “high” level, allowing current to flow to the resistor and be converted to heat. When the DC bus voltage drops to a predefined “low” level, the IGBT is switched off.

Pulse-width modulation control, on the other hand, switches the IGBT on-and-off continuously via a control algorithm and monitoring of the DC bus voltage, so torque ripple is greatly reduced. PWM control is primarily used when multiple drives are connected to a common DC bus, to avoid having one drive doing a disproportionate share of the dynamic braking work.

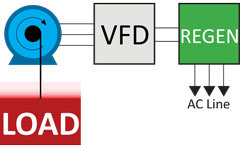

Regenerative braking takes the energy generated by the motor and feeds it back to the AC power source or to a common bus, where it can be used again. Feeding the energy back to a common bus gives an additional benefit in terms of efficiency, because the power is converted from AC to DC only one time. In contrast, if the power is passed back to the AC supply, it needs to be converted back to DC again when it’s reused by the drive, so there are additional losses.

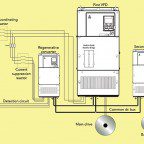

Image credit: Bonitron

Because dynamic braking is based on dissipating power as heat through resistors, it is used for applications that require periodic dissipation or when deceleration speeds vary. Regenerative braking is preferred when there are frequent stops, constant deceleration, or overhauling loads.

Although regenerative drives have relatively higher up-front costs than simple dynamic braking systems, regeneration can often be justified when a large amount of energy can be recovered or when the cost of the recovered energy is high.

Leave a Reply

You must be logged in to post a comment.