Now there’s one-click access to documentation, service requests and more for WITTENSTEIN alpha gearheads.

In another industry first, WITTENSTEIN Inc. has launched a new Online Service Portal that provides OEMs and end users with personalized product information in minutes. All of the LP model planetary gearheads (produced at WITTENSTEIN’s North American headquarters in Illinois) now feature access to this service portal.

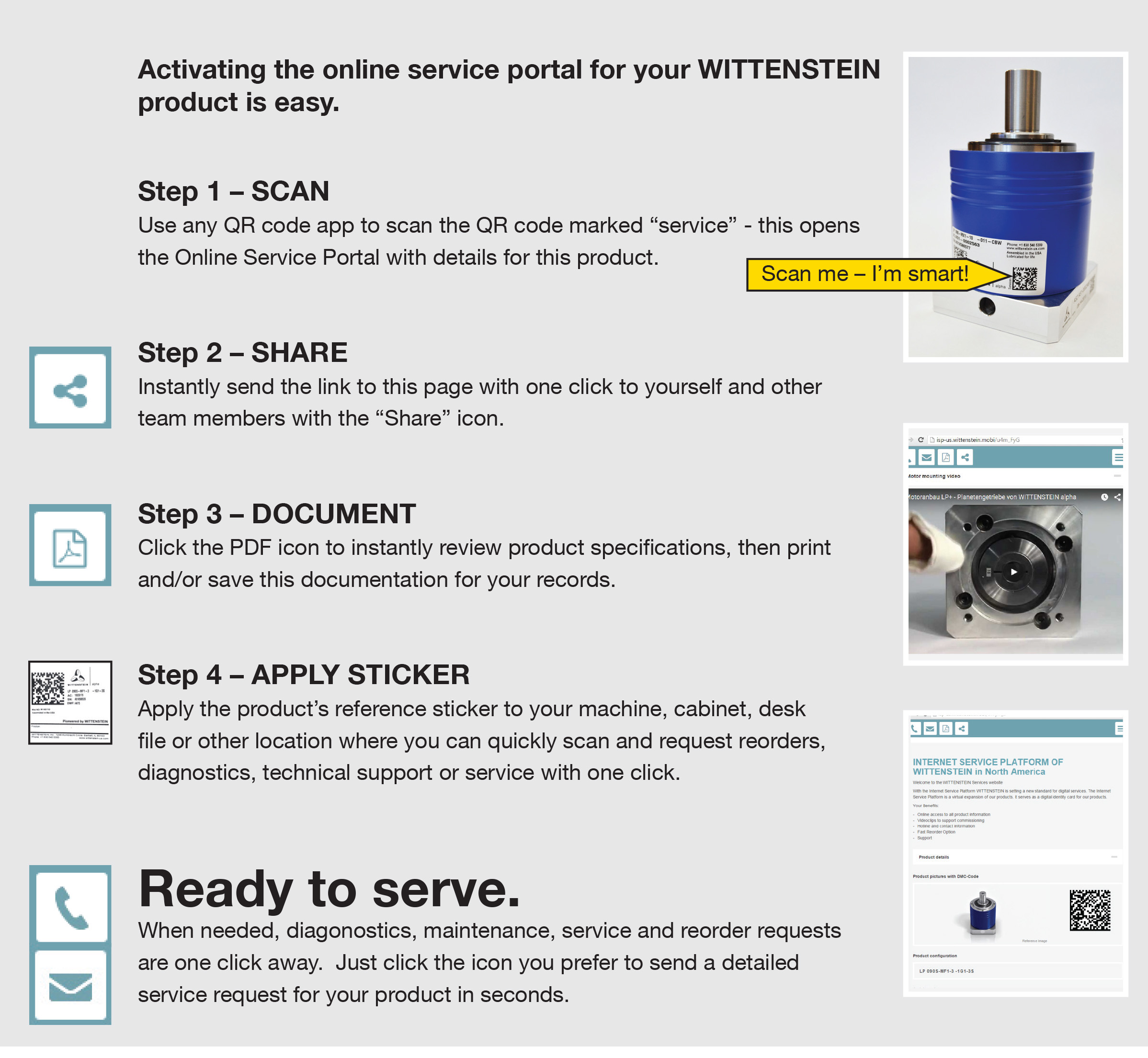

How the WITTENSTEIN Online Service Portal works

To access the WITTENSTEIN Online Service Portal, customers simply utilize any QR Reader application to scan the QR code labeled “Service” on their WITTENSTEIN alpha gearhead.

The application then opens a unique web page for that individual product, which features purchase information, technical specifications, installation instructions, documentation and other helpful information. All of this information can be easily reviewed, shared and archived as PDF files for future reference.

New levels of speed and service

In addition to expediting product documentation, the WITTENSTEIN Online Service Portal dramatically speeds service and maintenance requests. Instead of disassembling the machine or trying to crawl inside to access the QR code on the component, end user customers utilize a machine sticker included with the product, which has been placed in a machine cabinet or accessible location nearby. The scan opens the Online Product Portal, and with one click the customer can send a service request email to WITTENSTEIN that includes all pertinent product data.

Because detailed product information is included with the service request, the WITTENSTEIN service department can more proactively address the specific needs of the customer. The service department can also provide diagnostic reporting.

“WITTENSTEIN’s reputation for quality and innovation in the industry puts us in a leadership spotlight, a trusted resource for guidance and expertise,” notes Dr. Lars Aldinger, Executive Vice President of Production & Logistics.

“This latest tool helps our customers directly impact their bottom line — saving time and resources. Combined with the integrity of our products and services, this tool directly helps optimize cost of ownership,” adds Aldinger.

The vast majority of core WITTENSTEIN alpha product is produced at the North America headquarters in Bartlett, Illinois. As part of its commitment to local production, the facility completed its first phase of Industry 4.0 preparations in July of 2015. These updates included:

• New Internet 4.0 machines

• Additional assembly lines

• Expanded in-stock inventory

• Onsite service and technical support

• Next-day delivery of LP units — assembled onsite in the U.S.

Elaborating on this commitment, Director of Sales Tom Coyle attests:

“Remaining accessible and easy to work with is a top priority for WITTENSTEIN here in the U.S. We are investing significantly to deliver even more product, support and services to all our customers – which includes distributors, OEMs and end users. And we will be taking this to the next level later this year with new products produced right in Bartlett.”

Here’s a piece of literature that explains how to setup a part for Portal-accessible data … click on the image to download a PDF of it and more information about the Online Service Portal in general:

About WITTENSTEIN Inc.

Located in Bartlett, Illinois, WITTENSTEIN Inc. produces components that deliver the utmost precision and system performance. From low-backlash planetary gearheads to complete mechatronic drive systems, our products set benchmarks worldwide in machine building and drive technology. The Bartlett facility serves as the North American headquarters

Leave a Reply

You must be logged in to post a comment.