Rolling bearings feature especially low friction characteristics, making it possible to reduce bearing friction by half, and offering the construction machinery sector the opportunity to achieve significant carbon dioxide savings without imposing high development costs.

Stefan Scharting

Schaeffler KG

Schweinfurt, Germany

Rolling bearings with optimized friction and performance characteristics can have a significant influence when it comes to reducing the power loss, design envelope, and weight of hydraulic motors and pumps, as well as gearboxes and axles in construction machinery. If correctly designed, rolling bearings can make a significant contribution to reducing carbon dioxide emissions.

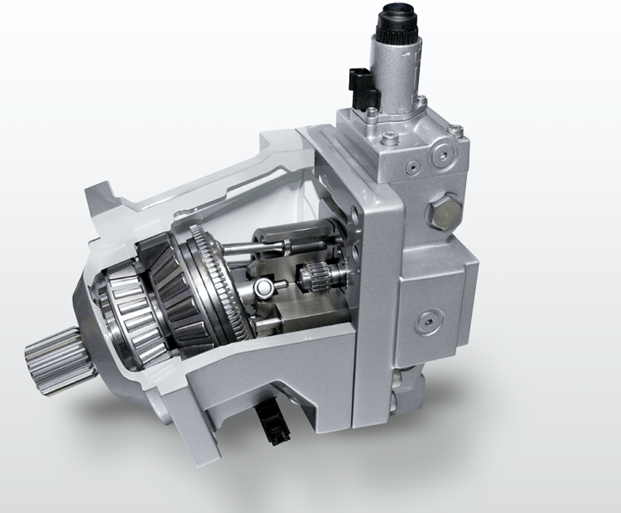

Reduced friction, higher dynamic load ratings

The vast majority of today’s construction machinery is still operated conventionally, using diesel engines and hydraulic components. In the widely used adjustable axial piston pumps and motors, the input and output shaft are usually supported by two tapered roller bearings that are adjusted against each other. When designing the bearing support, it’s advisable to reduce the preload to precisely the required minimum allowed by the load spectrum. The lower bearing preload leads to permanently lower axial forces between the tapered roller end face and inner ring rib and, therefore, to a corresponding reduction in frictional torque.

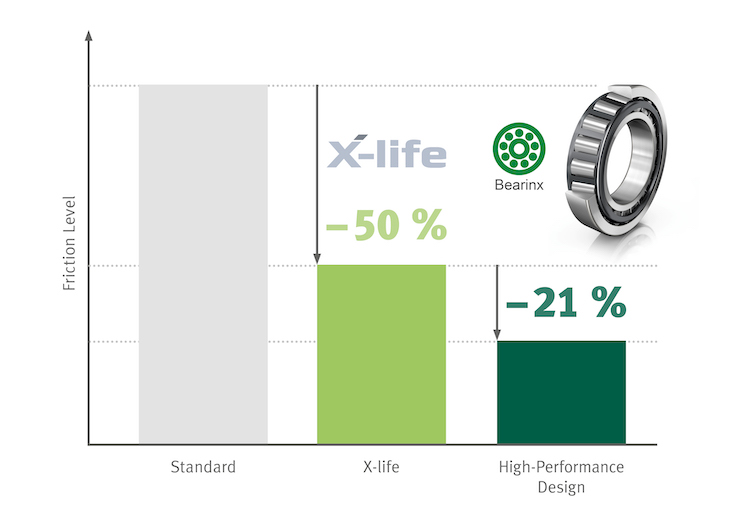

Tapered roller bearings in X-life quality from Schaeffler are another option for reducing friction without making a design change. Friction can be halved compared to conventional bearings through specially machined raceway and roller surfaces as well as optimized geometry in the contact between the end face of the rolling element and the inner ring rib. Even at the low speeds during the start-up process, an elastohydrodynamic lubricant film forms due to the improved surfaces and osculations, which reduces the wear and friction under the already low viscosity lubrication conditions.

The optimizations to the internal design also led to a significant noise reduction along with approximately 25 percent higher dynamic load ratings as compared to standard tapered roller bearings, resulting in a calculated rating life increase of more than 100 percent. Similar progress can be achieved by using cylindrical roller bearings in X-life quality. The high dynamic load ratings allow a changeover from full-complement cylindrical roller bearings to cage-guided cylindrical roller bearings with significantly less friction.

For rolling bearings and, in particular, for cylindrical roller bearings with radial and axial loads as well as tapered roller bearings, specialized coatings can be used to reduce friction. For instance, Schaeffler offers its proprietary friction-reducing coating known as Triondur C. This diamond-like carbon coating is specifically optimized for loads in the rolling element contact and reduces the friction in a dry steel-to-steel contact by around 80 percent.

There are other methods for reducing friction as well. For example, downsizing or a higher power density is not only associated with a lower consumption of materials and energy during manufacturing; it also leads to reduced friction in drive systems. As described above, rolling bearings in X-life quality offer the required reserves thanks to their load ratings. With high-performance rolling bearing steels, such as Cromadur from Schaeffler, it’s possible to unlock further potential for increasing the power density.

These friction-reducing methods can be complemented by the use of CAE tools. Case in point: using specialized simulation software, Schaeffler is able to achieve efficiency improvements as early as during the product-development phase. For example, with the aid of computational fluid dynamics (CFD) simulations, it’s possible to reduce the churning losses in hydraulic units and gearboxes to a minimum. Schaeffler’s Bearinx design and simulation software allows efficient optimization of bearing supports. Bearinx’s “OptiKit” optimization module can compare various load case analyses or also determine suitable parameters for specific target values, so that, for example, the optimum bearing preload can be calculated.

Verifiable savings potential

By using X-life tapered roller bearings in combination with optimized preload, it was possible to increase the efficiency of hydraulic pumps and hydraulic motors by approximately 2 percent in efficiency projects. Accordingly, a wheel loader equipped with such an optimized hydraulic pump and two hydraulic motors could yield a significant 6 percent energy savings. For a drive power of 140 kW, this corresponds to around 9 kW. Extrapolated to 1,000 wheel loaders working for eight hours per day, this results in an annual savings potential of around 26,000 MWh, which amounts to a savings of approximately 16,000 tons of carbon dioxide.

The solutions for not only hydraulic drives as described above, but also for gearboxes, differentials and axle drives, allow the frictional torque generated by rolling bearings to be reduced by half using standard catalog products. By exploiting all the possibilities, including a bearing design that is based on the load spectrum of the customer’s application, Schaeffler has verified a friction reduction of more than 71 percent as compared to conventional catalog bearings.

Basics of rolling bearings

Bearings transmit motion and forces and are usually mounted on axles or shafts and inserted in housings. If a bearing transmits rotary motion, it’s called a rotary bearing. Linear bearings are used for longitudinal motion. The type of friction involved distinguishes plain bearings from rolling bearings.

Plain bearings are components with a sliding layer between two parts. This sliding layer may be a solid layer that is fixed to the bearing, such as plastic or bronze layers. Otherwise, a lubricating film separates the surfaces.

Rolling bearings are bearings with two components that move in opposite directions. These parts are the inner and outer ring, and are separated by rolling elements. The rolling elements roll between the two rings during operation. This occurs on hardened steel surfaces called raceways. What’s more, the friction generated here is significantly lower compared to plain bearings.

Rolling elements are the most important parts in a bearing, because they carry most of the loads. Rolling elements come in different shapes such as balls, cylindrical rollers, needle rollers, tapered rollers or spherical rollers. The names of many bearing types are based on the kind of rolling element used, such as “ball bearing” or “needle roller bearing.”

In modern bearings, a cage is used to provide even spacing for the rolling elements, which prevents them from contacting each other. Cages can be made from sheet steel, plastic or brass.

Additional components may include sealing shields or seals. Another important part of a bearing is the lubricant. Rolling bearings are lubricated with grease or oil to extend operating life. The seal keeps the lubricant in the bearing and prevents dirt and moisture from entering.

Rolling bearing components and materials can be combined in numerous ways to produce a wide range of bearing designs. Special bearings are designed for special applications that are tailor-made for the specific needs of an application. Examples include bearings with several rings for high loads, combined ball and roller bearings, wheel bearings with built-in measuring systems, or high temperature bearings for aviation and aerospace applications.

Schaeffler KG

www.schaeffler.com

Leave a Reply

You must be logged in to post a comment.