Gearmotors use gears to reduce speed, which makes more torque available. The kind of gears used in gearmotors have an impact on the available torque, but also on things like noise levels and accuracy. In fact, one of the more common sources of inaccuracy in gearmotors is due to gear backlash. So reducing the amount […]

FAQs + basics

Most-read motion-control articles of 2022

As we close out the year of 2022, the staff of Motion Control Tips would like to present our most-read articles of this year. (5th) most read: Electric actuators — an alternative to hydraulic cylinders This article details how as electric rod-style actuators have become capable of outputting forces comparable to those of high-end hydraulics, […]

What determines worm gear efficiency, and is it really that low?

Worm gears are often used for their ability to provide very high reduction ratios (and high torque multiplication) in a compact, single-stage design. But traditional thinking says that these benefits come at the expense of efficiency. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide […]

Leading motion-control and actuation options for robotics

Advanced robotics for industrial and consumer applications demand sophisticated power-dense motion components for joints and linkages that must run smoothly, often at high torque and relatively low speed. The challenge is compounded when the robotic application must also make precise moves. At the core of most leading robotic-actuator options are electric motors. That’s because motor-driven designs […]

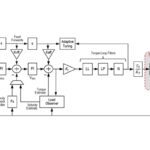

What are biquad and other filter types for servo tuning?

One way to improve servo system performance is to increase the gains in the control loop, allowing the system to respond faster to commands and to settle more quickly, with less oscillation. But increasing the servo gains means that any resonances in the system — typically due to mechanical compliance — are further amplified, which can […]

Automated foodservice with EtherCAT to disrupt restaurant industry

Now an industrial-appliance-sized design called the Makeline from food services company Hyphen is leveraging software, rugged automation, and networked controls to help labor-strapped restaurants meet modern business demands. “We founded the business in July 2018 to leverage automation technology in modern restaurants,” says Daniel Fukuba, Co-Founder and CTO of Hyphen. “Shortly thereafter, we built the […]

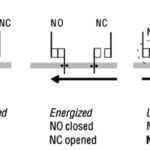

What is external device monitoring and how does it relate to machine safety?

According to the Machinery Directive 2006/42/EC, technical protective measures should be used to reduce risks that cannot be avoided through safe design measures. These technical protective measures include safety devices such as door locks, covers, light curtains, and other equipment that monitors the machine movements. When the safety device controls and external device, such as […]

What machine safety functions address speed, and when are they used?

The Machinery Directive 2006/42/EC states that when a machine manufacturer is unable to eliminate the risks of potential hazardous situations (for example, mechanical hazards such as crushing or cutting) through safe design methods, the next step is to reduce the risks through technical protective measures. These technical measures include protective devices, such as door locks […]

What is Machine as a Service (MaaS) and what are its benefits?

Most of us are familiar with the software as a service (SaaS) business model, in which users pay a fee to access software over the internet, without requiring an application or download to a local machine. The software as a service model made complex software, such as CRM (customer relationship management) systems, more accessible to […]

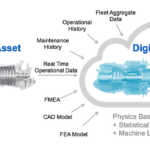

What are digital twins and how are they used in industrial manufacturing?

Manufacturing even the simplest product requires expertise in materials, equipment, operations, and process flow. And the interdependencies of these elements make it extremely difficult — if not impossible — to “get it right the first time” when setting up a new manufacturing line or modifying an existing process. Every element, from the product design to the […]