Worm gears are often used for their ability to provide very high reduction ratios (and high torque multiplication) in a compact, single-stage design. But traditional thinking says that these benefits come at the expense of efficiency. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide […]

What are biquad and other filter types for servo tuning?

One way to improve servo system performance is to increase the gains in the control loop, allowing the system to respond faster to commands and to settle more quickly, with less oscillation. But increasing the servo gains means that any resonances in the system — typically due to mechanical compliance — are further amplified, which can […]

What is external device monitoring and how does it relate to machine safety?

According to the Machinery Directive 2006/42/EC, technical protective measures should be used to reduce risks that cannot be avoided through safe design measures. These technical protective measures include safety devices such as door locks, covers, light curtains, and other equipment that monitors the machine movements. When the safety device controls and external device, such as […]

What machine safety functions address speed, and when are they used?

The Machinery Directive 2006/42/EC states that when a machine manufacturer is unable to eliminate the risks of potential hazardous situations (for example, mechanical hazards such as crushing or cutting) through safe design methods, the next step is to reduce the risks through technical protective measures. These technical measures include protective devices, such as door locks […]

What is Machine as a Service (MaaS) and what are its benefits?

Most of us are familiar with the software as a service (SaaS) business model, in which users pay a fee to access software over the internet, without requiring an application or download to a local machine. The software as a service model made complex software, such as CRM (customer relationship management) systems, more accessible to […]

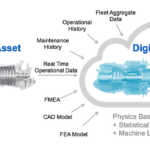

What are digital twins and how are they used in industrial manufacturing?

Manufacturing even the simplest product requires expertise in materials, equipment, operations, and process flow. And the interdependencies of these elements make it extremely difficult — if not impossible — to “get it right the first time” when setting up a new manufacturing line or modifying an existing process. Every element, from the product design to the […]

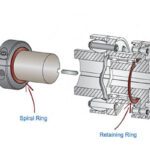

How to calculate retaining ring maximum speed (rpm), and when it matters

Selecting an appropriate retaining ring for an application typically involves evaluating factors such as installation stress, the radial load exerted by the ring, and the thrust capacity of the ring. And because the groove that holds the ring is integral to the ring’s performance, groove deformation needs to be considered as well. But when an external […]

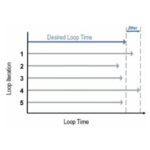

What are latency and jitter and why are they important to industrial networks?

Applications that use closed-loop control often require communication networks that provide deterministic, real-time control of data transmission. This means the network guarantees that a message will be transmitted, or an event will be responded to, in a specified, predictable period of time — not faster or slower (deterministic) — and that the message will be transmitted […]

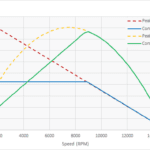

When is motor output power a useful specification and how is it calculated?

In motion applications, motors are typically chosen based on their torque and speed capabilities, using a torque-speed curve that describes the motor’s performance when paired with a specific type of drive and operated under specific conditions. But motors can also be rated, or specified, by their output power. Here, we’ll look at how output power […]

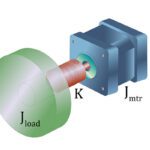

Motion system design: How to manage inertia mismatch

One of the most important parameters when sizing a motion system is the inertia of the load being moved. Regardless of the type of motor being used — AC induction, stepper, brushless DC, or AC servo — the ratio of the load inertia to the motor inertia has an important influence on system performance. If the […]