In motion applications, motors are typically chosen based on their torque and speed capabilities, using a torque-speed curve that describes the motor’s performance when paired with a specific type of drive and operated under specific conditions. But motors can also be rated, or specified, by their output power. Here, we’ll look at how output power is calculated and when this is a useful specification for selecting a motor.

Relationship between work and power

Before discussing power, we need to define work…

Work is force applied over a distance and is expressed in units of joules (1 J = 1 Nm) or lb-ft.

![]()

W = work (J, lb-ft)

F = force (N, lb)

d = distance (m, ft)

Power is the amount of work done over time and is expressed in units of watts (1 W = 1 J/s) or horsepower (hp).

![]()

P = power (W, hp)

t = time (s)

Using the definition of work, power can also be written in terms of force, distance, and time.

![]() Since distance divided by time is velocity, we can express power in terms of force and velocity.

Since distance divided by time is velocity, we can express power in terms of force and velocity.

![]()

v = velocity (m/s, ft/s)

But electric motors produce torque rather than force, and they rotate with an angular velocity rather than linear velocity. So for electric motor applications, output power is found by multiplying the motor’s rotational speed (angular velocity) by its torque output at that speed.

![]()

T = torque (Nm, lb-ft)

ω = angular velocity (rad/s)

Note that angular velocity is expressed in radians per second (rad/s). If the motor’s speed is given in rotations per minute (rpm), be sure to convert this to the correct units of rad/s.

![]()

Nm and lb-ft: Work or torque?

Although work and torque have the same units (Nm or lb-ft, for example), work is a scalar quantity, meaning it has a magnitude but no direction. Torque, on the other hand, is a vector quantity, meaning it has both magnitude and direction. This is why torque can have a negative value, depending on the direction of rotation, but work can only be positive.

When is power used as a motor specification?

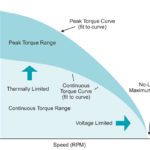

Because the power rating of a motor is determined by its rated speed and torque production at that speed, motors that operate at constant speed and relatively constant torque, such as AC induction motors, often use output power as a key specification.

However, output power isn’t a very useful specification for servo or stepper motors, since they operate over a wide range of speeds and output torque values.

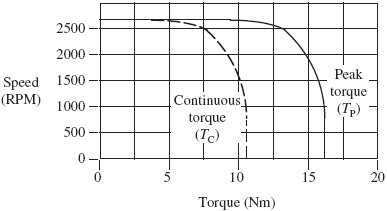

Image credit: George Ellis, Elsevier

For DC motors, the torque-speed curve is relatively linear, so maximum power output occurs when the motor is operating at a point that corresponds to approximately one-half of the stall torque and one-half of the no-load speed.

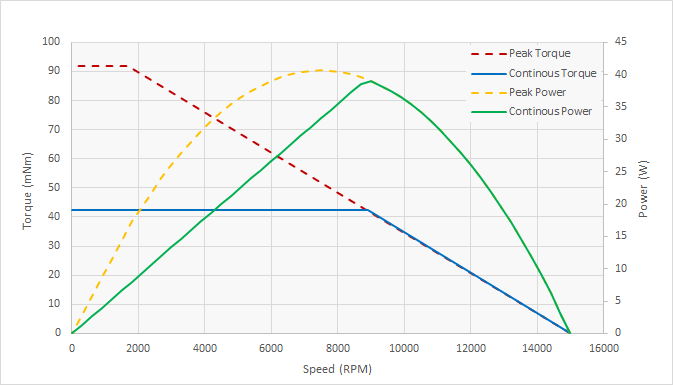

Image credit: Electrocraft

The unit of horsepower was introduced in the 1780s by James Watt and Matthew Boulton, who defined 1 horsepower (hp) as 33,000 ft-lb/min, which equals 44,742 Nm/min or 746 Nm/s. Since 1 Nm/s = 1 J/s = 1 W, 1 hp = 746 W.

Leave a Reply

You must be logged in to post a comment.