By Gloria Hu-JIECANG Overseas Marketing Manager Recently, Fulongma, an environmental sanitation solution provider, launched the world’s first skateboard-based sweeper robot, which is equipped with the JIECANG intelligent electric linear actuator products. The sweeper can operate fully automatically and has high mobility and driving ability. It provides all-round, efficient, intelligent cleaning services for multiple areas, such […]

Linear Motors

What are Sawyer motors and where are they used?

Originally named for Bruce Sawyer, who patented the design in 1968, Sawyer motors are a type of planar motor, and are sometimes referred to as “dual-axis linear stepper motors” since they use stepper motor technology and the moving part can travel in both the X and Y directions. Like other planar motor designs, Sawyer motors […]

New miniature linear voice coil motors from Moticont

The new LVCM-010-013-01 linear voice coil motor from Moticont is only 0.375 in. (9.5 mm) in diameter and the length at mid-stroke is just 0.81 in. (20.7 mm) long. However, this new miniature voice coil motor has a high force-to-size ratio with a continuous force of 1.0 oz (0.28 N), a peak force of 3.2 […]

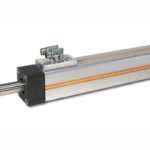

Direct-drive linear motor features integrated encoder, temperature sensor

The new patented SDLM-019-070-01-01 direct-drive linear motor with integrated position and temperature sensors is the latest addition to the series of zero backlash, zero cogging, high acceleration, high speed, high resolution, long life motors from Moticont. Also known as an electric cylinder, this compact direct-drive linear motor is just 0.75 in. (19.1 mm) in diameter […]

When do tubular linear motors outperform traditional iron core and ironless designs?

In a recent post, we looked at traditional iron core and ironless linear motors, both of which have a flat-type construction. But another type of linear motor, often referred to as a “tubular linear motor,” is also gaining traction in industrial applications. This is especially true in the packaging and medical industries, where tubular linear motors […]

3 things to consider when choosing a linear servo motor

Direct drive linear servo motors have seen a measurable increase in adoption over the past several years, thanks in part to end users’ demands for higher throughput and better precision. And although linear motors are most often recognized for their ability to provide a combination of high speeds, long strokes, and excellent positioning accuracy that […]

How to specify motion components for cleanroom environments: Part 2

In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we looked at how to reduce particle generation due to friction between moving components. In this second part, we’ll look at another source of contamination — outgassing — […]

How to specify motion components for cleanroom environments: Part 1

In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we look at how to reduce particle generation due to friction between moving components. Designers of automation systems are tasked with many competing demands, such as balancing cost and performance, […]

Hybrid linear stepper motors: Operation and applications

Like servo motors, stepper motors are available in both rotary and linear designs. When an application requires force (rather than torque) output and can operate in open loop control, a linear stepper motor is often the preferred solution. Although linear stepper motors are available in both variable reluctance and hybrid designs, the more common version is […]

Five key electrical design concepts for mechanical engineers

Edited by: Paul J. Heney, Editorial Director Mechanical engineers often overlook important electrical issues when specifying their respective parts of an electromechanical system. This targeted advice will help you design your next electromechanical system. Mechatronic systems are the state-of-the-art technology in automation systems, intelligently integrating mechanical and electrical elements to perform increasingly complex and demanding […]