Originally named for Bruce Sawyer, who patented the design in 1968, Sawyer motors are a type of planar motor, and are sometimes referred to as “dual-axis linear stepper motors” since they use stepper motor technology and the moving part can travel in both the X and Y directions.

Like other planar motor designs, Sawyer motors consist of a moving part — typically referred to as the forcer — and a stationary part, referred to as the platen. (Single-axis versions of Sawyer motors also exist, but these designs are essentially single-axis linear stepper motors.)

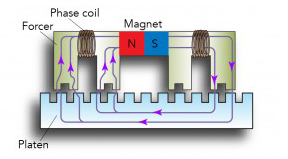

The forcer is typically made of aluminum and contains four coil assemblies, with each coil assembly made up of the motor windings (coils) and a permanent magnet. The coil assemblies can be 2-phase or 4-phase, with 4-phase designs providing approximately twice the resolution as 2-phase designs. The active (bottom) surface of the forcer is slotted to form teeth, which concentrate the magnetic flux that’s created when current is applied to the coils.

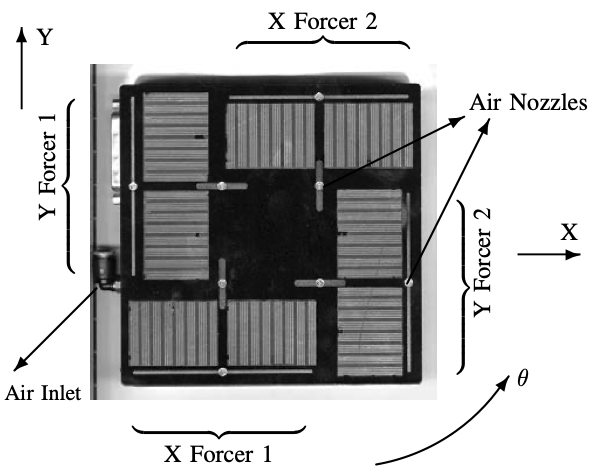

Two coil assemblies are mounted in series to provide motion in the X direction, and the other two coil assemblies are mounted orthogonal to the first two, providing motion in the Y direction. The forcer also contains an air bearing system to support the weight of the forcer and the applied load.

Image credit: H2W Technologies

The platen is typically a ground steel plate that is also slotted to form teeth. The result is a waffle-like structure, and the spaces between the teeth are filled with epoxy. The platen serves as the air bearing surface, and the attractive force between the forcer and the platen provides a magnetic preload on the air bearing system.

Since they use stepper motor technology, Sawyer motors are designed to run as open-loop systems, but closed-loop operation can be achieved with the addition of two encoder positioning sensors — one for each direction of movement — to detect lost steps. (The position sensor acts like an incremental encoder, but rather than using a linear scale, it works in conjunction with the platen to determine position.) Although full-step operation is possible, most dual-axis linear stepper motors are operated with microstepping control for high resolution.

As with other planar motor designs, Sawyer motors can use multiple, independent forcers on the same platen for complex, coordinated motions. And due to the construction of the forcer, these designs can also provide rotational (theta) motion over several degrees. Sawyer motors can also be wall-mounted or inverted (mounted upside-down).

The main benefits of Sawyer motors are their relatively low cost (even with closed-loop operation) and ease of use, with no servo tuning required. Despite their relatively simplicity, Sawyer motors operated with microstepping drives are common in high-precision semiconductor processing applications, such as wafer steppers, wafer probers (for testing), and wire bonders. These planar stepper motor designs are also used in assembly and pick and place applications in drug discovery and MEMS industries.

Leave a Reply

You must be logged in to post a comment.