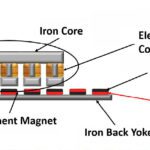

Iron core linear motors are known for their high continuous and peak force capabilities, good thermal management, and excellent force-to-size ratio. But they’re also known to produce cogging forces, which lead to force ripple, or variation in output force. But how much of a problem is cogging for iron core linear motors, and what are […]

What are recipes in the context of HMIs?

Many companies offer a range of products that are variations of a “base” model, using many of the same components, manufacturing methods, and processing steps to keep inventory and manufacturing costs under control while still providing customers with a range of choices to fit their exact needs. Automobiles are an excellent example. Take the Ford […]

ATEX and IECEx classifications and markings explained

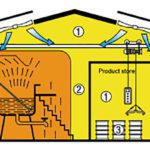

When electrical equipment is used in a potentially hazardous location — one that contains flammable gases, vapors, liquids, dust, or fibers — it’s important that the potential for fire or explosion be minimized. One way to do this is to use equipment that has been certified as suitable for that environment and not likely to […]

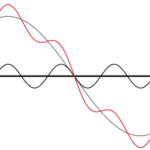

What are harmonics and how do they affect motion control systems?

Harmonics are voltages or currents caused by non-linear loads on a power supply. Harmonic frequencies occur at integer multiples of a fundamental frequency and are superimposed on the fundamental voltage or current waveform, creating a distorted waveform. Harmonics are classified first by their order, or the integer multiple of the fundamental frequency. For example, for […]

Classifying hazardous locations: What’s the difference between Class, Division, and Zone?

According to the National Fire Protection Association, a hazardous location is an area where fire or explosion hazards may exist due to electrical equipment operating in the presence of flammable or ignitable gases, liquids, or vapors, or in the presence of combustible dust, fibers, or flyings. But even within this definition, the risk of fire or […]

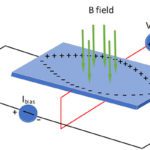

How do Hall effect sensors work and where are they used in motion applications?

The Hall effect is an outcome of the Lorentz force at work. When a thin conductor (or semiconductor) has a steady flow of current running through it and a magnet is placed so that its magnetic field runs perpendicular to this current, the magnetic field of the current reacts to the magnetic field of the […]

What to consider when choosing a rotary encoder

Controlled servo drives are used in many areas of automation technology, converting, printing, handling, and robotics, including production machines and machine tools. The selection of a rotary encoder or encoder technology for use within the system depends on the accuracy requirements of the application and whether the application will use position control, velocity control, or both. […]

Why do servo drives use PWM and how does it work?

The basic function of a servo drive is to convert, or amplify, low-power signals from the controller into higher-power signals to be delivered to the motor windings. Servo drives (also referred to as servo amplifiers) can be either linear or switching types, depending on how power is delivered to the motor from the switching devices […]

When is dither helpful in motion control systems?

Dither is one of several terms used to describe small, rapid, back-and-forth movements of an object. Depending on the context, when the term “dither” is used in motion control systems, it can refer to purposeful, commanded movements or to unintended, unwanted motion. In some motion systems, dither is purposely induced to reduce the effects of […]

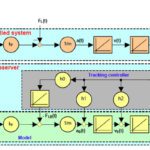

What is an observer in motion control and how does it affect performance?

A servo control loop uses sensor feedback to determine whether the system’s actual state (position, velocity, or torque) matches the commanded state. But sensors feedback isn’t perfect — even high-quality encoders and sensors can introduce noise, phase lag, and other errors in measurement. One way to improve the feedback of a servo control system is […]