Many companies offer a range of products that are variations of a “base” model, using many of the same components, manufacturing methods, and processing steps to keep inventory and manufacturing costs under control while still providing customers with a range of choices to fit their exact needs. Automobiles are an excellent example. Take the Ford Bronco and Ranger models. Both vehicles are built on the same platform and use much of the same hardware, with different body and trim pieces. So a production line that’s set up to assemble Rangers can be switched over to assembling Broncos with just a few (relatively speaking) changes of parts, equipment, and programming — as opposed to a full-scale reconfiguration of the production line.

This model — where multiple variations are produced on the same manufacturing or assembly line — exists for all types of products, from powdered drink mixes to bearings. And as companies increasingly adopt flexible manufacturing systems, product changeovers from one variation to another become more frequent — as often as daily or even multiple times per day. But these changeovers can consume valuable production time as operators manually adjust control parameters from one product to the next. This is where recipes come in.

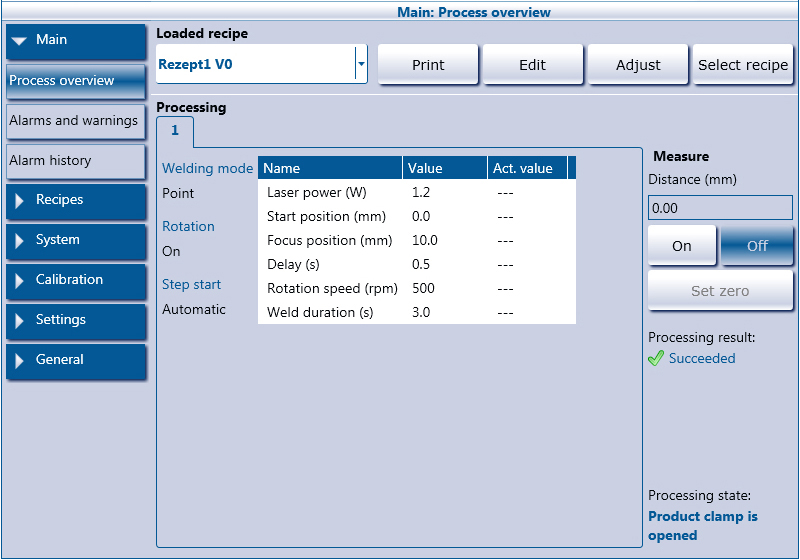

Recipes are sets of parameters that are stored in an HMI and can be transferred directly to a PLC or controller to enable fast, error-free product changeovers.

Image credit: BW-TEC

A key characteristic of recipes is that they contain only the parameters, or variables, that change from one product to the next. These variables can be materials such as hardware, processing steps such as whether to drill a hole or not, or machine parameters such as the depth of the hole to be drilled.

For example, if a product range consists of panels that come in three sizes — 150 x 150 mm, 300 x 300 mm, and 450 x 450 mm —and each panel size is assembled using different screws, recipes could be used to specify which screw size to use with which panel size. Similarly, an inspection operation that tests the torque of the assembly screws could use recipes to specify different torque values for different screw sizes.

Most HMIs include (or can be configured with) a recipe feature, which allows recipes to be created, modified, saved in a database, and uploaded to or downloaded from a PLC or controller. Recipes are often created and managed in a spreadsheet format, and the recipe data can be imported and exported — typically as a CSV file — between the HMI and a USB drive or SD card, making it easier to modify the data using a program such as Excel or a text editor. And some HMI recipe functions allow recipes that have been modified in the PLC or controller to be uploaded to the HMI as a new version and saved to the recipe database.

Although HMI manufacturers use different terminology for the elements of a recipe, every recipe consists of a “master” recipe, which contains all the variations of the product. For example, the master recipe for the Panel Assembly described above would contain three recipes: one for Panel 150 x 150, one for Panel 300 x 300, and one Panel 450 x 450. The recipe data — the specific screw sizes used for each Panel recipe — are associated with HMI tags where the data will be stored.

Recipes in process industries

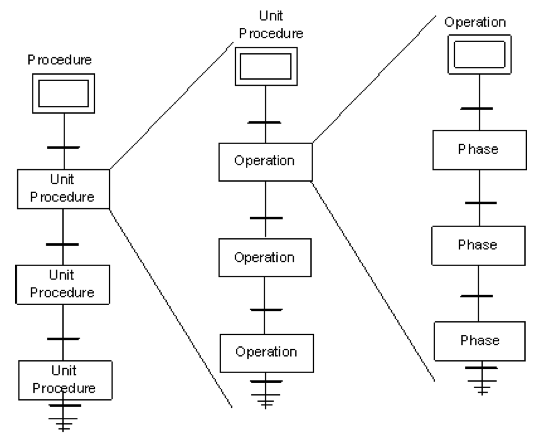

For batch process applications, where processing steps depend on specific pieces of equipment — for example, mixing components A and B must be done by machine X — recipe development becomes more complex, with more variables and dependencies. But HMI manufacturers offer tools, such as Sequential Function Chart (SFC) language, that graphically organize recipes into procedures, unit procedures, and operations. In fact, batch processing industries often follow the ANSI/ISA-88 standards for Batch Control Models and Terminology. Among other things, this standard aims to “…make recipe development straightforward enough to be accomplished without the services of a control systems engineer…”

Image credit: General Electric Company

Recipe or formulation?

Some people make a distinction between recipes and formulations. In this terminology, “formulation” indicates that the steps used to make the various products are the same and only the ingredients or materials change. The term “recipe,” on the other hand, is used when both the formulation (ingredients or material) and the production steps vary between products. With this distinction, recipes are most widely used in processing industries such as food and beverage, pharmaceuticals, and chemicals, whereas formulations are more prominent in manufacturing industries where several products may have different bills of material, but their production method or assembly sequence is the same.

For example, in a packaging application, formulations would be used to facilitate quick changeovers of a pick-and-place operation that crates various sizes of spice bottles for shipping. This example would qualify as a formulation (rather than a recipe) because the location of the bottle’s surface to be gripped would change among the various bottle sizes, but the general pick-and-place operation would be the same for each size of bottle. On the other hand, recipes would be used for producing batches of different kinds of spice blends. Not only would the ingredients change with each spice blend, but some blends may require fine grinding, while others might only need coarse mixing. Hence, both the ingredients and the processing steps change with the various products.

Despite this distinction, the term “recipe” is preferred in the industrial automation world, regardless of whether both the materials and production steps vary, or only the materials vary from one product to the next.

Leave a Reply

You must be logged in to post a comment.