According to the National Fire Protection Association, a hazardous location is an area where fire or explosion hazards may exist due to electrical equipment operating in the presence of flammable or ignitable gases, liquids, or vapors, or in the presence of combustible dust, fibers, or flyings. But even within this definition, the risk of fire or explosion and the conditions necessary to create those hazards vary, depending on the hazardous material that may be present and the probability and degree of its presence. To address the importance of choosing equipment that can safely operate in hazardous locations, the U.S., Canada, and the European Union have developed standard methods for classifying areas where hazardous atmospheres may occur.

In the U.S., the dominant standard for classifying hazardous locations is the National Fire Protection Association Publication 70 National Electric Code. Also referred to as NFPA 70 NEC, this standard uses a system of Classes and Divisions that, when combined, specify the hazardous conditions of an area.

Outside of North America, the IEC 60079 series of Standards for Explosive Atmospheres is the most commonly used classification system. The IEC 60079 series uses a system of Zones, which indicate the level of probably that a flammable concentration of a hazardous substance may be present in an area.

Although the Class/Division system for identifying hazardous locations is the predominant system in the U.S., NFPA 70 NEC has added an alternative classification system based on Zones, similar to the IEC system. (It’s important to note that in the U.S., the Zone system is more prevalent in the chemical and petrochemical industries, while the Class/Division system is used in most other industries.)

The Canadian Electrical Code (CEC) is similar to NFPA 70 NEC, providing both Class/Division and Zone classification systems. However, since 1998, the CEC has required that new installations be classified according to the Zone system.

Classes and Divisions

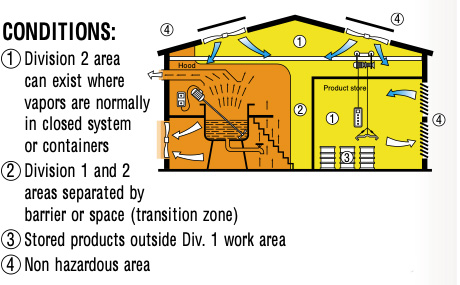

The Class and Division system — used in NFPA 70 NEC and the Canadian Electrical Code — establishes classifications that indicate the hazardous conditions of a specific area.

Classes indicate the type of hazardous substance that is or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

- Class I – flammable gases or vapors

- Class II – combustible dust

- Class III – easily ignitable fibers or flyings

Divisions indicate the probability of the hazardous substance being able to produce an explosive or ignitable mixture based on its presence.

- Division 1 – Ignitable concentrations of the hazardous substance exist under normal operating conditions and/or where the hazard is caused by frequent maintenance or frequent equipment failure; or where easily ignitible fibers or flyings are handled, manufactured, or used.

- Division 2 – Ignitable concentrations of the hazardous substance exist under abnormal operating conditions; or where fibers or flyings are stored or handled other than in the process of manufacture.

For example, a Class I, Division 2 location is one where flammable gases or vapors may be present, but where ignitable concentrations exist under abnormal operation conditions (not under normal operating conditions or due to frequent maintenance or equipment failure).

Image credit: EGS Electrical Group

Groups are used with the Class/Division system to define the type of hazardous substance, based on its physical properties and the ease with which it can be ignited.

- Groups A, B, C, and D are used for gases

- Groups E, F, and G are used for dust and flyings (and so are only applicable to Classes II and III)

Zones

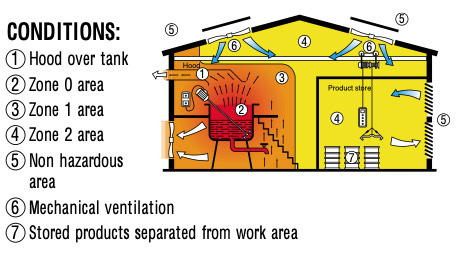

The Zone system for classifying hazardous locations — used in NFPA 70 NEC, IEC 60079, and the Canadian Electrical Code — indicates the level of probability that a flammable concentration of a hazardous substance may be present. There are two sets of Zones: Zones 0 thru 2 are used for gases, vapors, and mists, and Zones 20 thru 22 are used for dust, fibers, and flyings.

Gases, vapors, and mists

- Zone 0 – Ignitable concentrations of flammable gases or vapors are present continuously or for long periods of time.

- Zone 1 – Ignitable concentrations of flammable gases or vapors are likely to exist under normal operating conditions or may exist frequently due to repair, maintenance, or leakage; or equipment is operated in a manner that equipment breakdown or faulty operation could result in the release of ignitable concentrations of flammable gases or vapors and cause failure of electrical equipment such that the electrical equipment becomes a source of ignition; or the area is adjacent to a Zone 0 location from which ignitable concentrations of vapors could be communicated.

- Zone 2 – Ignitable concentrations of flammable gases or vapors are not likely to occur under normal operating conditions, and if they do, will be present for only a short period of time; or volatile flammable liquids, gases, or vapors are confined within closed containers or systems and can escape only as a result of an accidental rupture; or volatile flammable liquids, gases, or vapors are normally prevented by positive mechanical ventilation, but may become hazardous due to system failure; or the area is adjacent to a Zone 1 area from which ignitable concentrations of flammable gases or vapors could be communicated.

Image credit: EGS Electrical Group

Dust, fibers, and flyings

- Zone 20 – Combustible dusts or ignitable fibers or flyings are present continuously or for long periods of time.

- Zone 21 – Combustible dusts or ignitable fibers or flyings are likely to exist under normal operating conditions or may exist frequently due to repair, maintenance, or leakage; or equipment is operated in a manner that equipment breakdown or faulty operation could result in the release of ignitable concentrations of combustive dusts or ignitable fibers or flyings and cause failure of electrical equipment such that the electrical equipment becomes a source of ignition; or the location is adjacent to a Zone 20 location from which ignitable concentrations of dust or ignitable fibers or flyings could be communicated.

- Zone 22 – Combustible dusts or ignitable fibers or flyings are not likely to occur under normal operating conditions, and if they do, will be present for only a short period of time; or combustible dusts or ignitable fibers or flyings are confined within closed containers or systems and can escape only as a result of abnormal operation of the equipment with which the dust or fibers or flyings are handled, processed, or used; or the location is adjacent to a Zone 21 location from which ignitable concentrations of dust or ignitable fibers or flyings could be communicated.

Like the Class/Division system of NFPA 70 NEC, The IEC Zone classification system also uses Groups to define the hazardous substance in more detail, based on its ignition temperature and explosion pressure. However, the Group designations in the IEC Zone system are different from those in the NEC hazardous locations classification system.

Leave a Reply

You must be logged in to post a comment.